Elevating Vehicle Safety through Advanced Brake System Maintenance

In the realm of automotive safety, the brake system stands as a pivotal component that demands meticulous attention and expert-level maintenance strategies. Ensuring the reliability of your brakes not only prolongs vehicle lifespan but also significantly enhances safety on the road, particularly in unpredictable driving conditions. This article delves into sophisticated maintenance techniques grounded in engineering principles, emphasizing preventative measures that preempt costly failures and optimize performance.

Deep Diagnostic Procedures for Detecting Hidden Brake System Anomalies

Effective maintenance begins with comprehensive diagnostics. Advanced diagnostic tools, such as brake fluid analyzers and electronic wear sensors, enable technicians to detect subtle issues like moisture contamination or caliper sticking that are not visible during routine inspections. Referencing industry standards outlined by the National Highway Traffic Safety Administration, proactive diagnostics are vital for preempting brake failures. Regularly scheduled diagnostics, aligned with manufacturer recommendations, serve as an essential cornerstone for maintaining optimal brake performance.

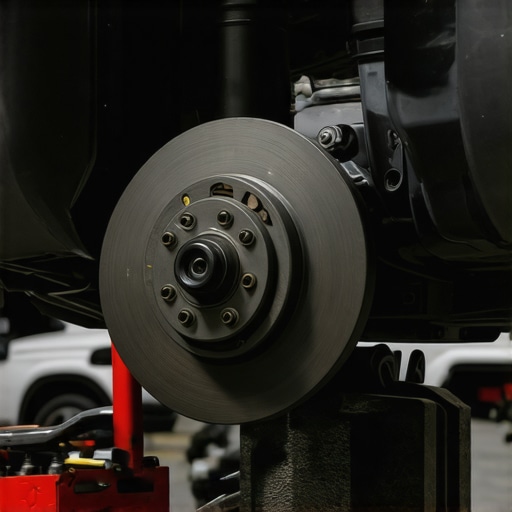

Harnessing Material Science for Enhanced Brake Durability

The evolution of brake pad and rotor materials plays a critical role in safety and longevity. Experts advocate for the adoption of semi-metallic or ceramic brake pads, which offer superior heat dissipation and reduced fade under high-stress conditions. Understanding the thermodynamics of friction materials, as detailed in recent research from the Materials & Design journal, enables technicians to select components that withstand rigorous driving demands while minimizing wear. This scientific insight translates into tangible safety benefits, especially in emergency braking scenarios.

Optimizing Brake Fluid Management for Consistent Performance

Brake fluid quality and maintenance are often underestimated yet are crucial for system reliability. High-performance brake fluids—such as DOT 4 or DOT 5.1—possess hygroscopic qualities that require regular replacement to prevent corrosion and vapor lock. An expert approach involves periodic fluid testing and timely flushing, which can be integrated into routine service schedules. This practice ensures hydraulic integrity, reducing the risk of pedal fade or complete failure during critical moments.

Expert-Level Questions on Brake System Reliability

What are the most effective methods for diagnosing subtle caliper sticking that eludes standard inspection procedures?

Addressing this question involves leveraging advanced diagnostic techniques like thermal imaging cameras to detect uneven heat distribution, indicative of caliper sticking. Additionally, performing dynamic brake tests under controlled conditions can reveal inconsistencies in brake engagement. Modern diagnostic software, combined with mechanical inspection, forms a comprehensive approach that enables experts to identify and rectify hidden issues before they compromise safety.

Empowering Vehicle Owners through Knowledge Sharing

For enthusiasts and professional mechanics alike, continuous education is essential. Engaging with specialized content, such as top brake service tips from trusted mechanics, enhances understanding of complex maintenance procedures. Sharing insights within professional communities fosters a culture of safety and innovation, ultimately leading to more resilient vehicle operation.

In conclusion, effective brake system maintenance is a multidimensional discipline that combines scientific understanding, technological proficiency, and proactive management. By integrating these expert strategies, vehicle owners and technicians can significantly reduce risks, prevent failures, and foster safer driving environments.

Refining Brake Inspection Techniques for Hidden Threats

While routine visual inspections are essential, relying solely on them can leave subtle issues unnoticed. Advanced inspection methods, such as ultrasonic testing for brake pads and rotors, enable technicians to detect internal cracks or delaminations that compromise safety. These sophisticated techniques align with the standards outlined by industry leaders like the National Highway Traffic Safety Administration, emphasizing the importance of scientific precision in preventive maintenance. Regularly updating inspection protocols to include these methods can dramatically reduce unexpected brake failures.

Utilizing Engineering Principles to Enhance Brake System Longevity

Understanding the physics behind braking—specifically heat transfer, friction, and material fatigue—helps technicians develop smarter maintenance routines. For example, applying the principles of thermodynamics can inform optimal cooling strategies, such as improved ventilation or heat-dissipating coatings on rotors. Incorporating these engineering insights, as detailed in recent studies from the Materials & Design journal, allows for more resilient brake components that resist warping and cracking. This scientific approach not only extends component lifespan but also enhances overall safety in demanding driving conditions.

The Role of Electronic Monitoring in Modern Brake Systems

Today’s vehicles increasingly integrate electronic sensors that monitor brake performance in real-time. Technologies like electronic wear sensors and ABS system diagnostics provide continuous feedback, alerting drivers and technicians to potential issues before failure occurs. This proactive monitoring aligns with the industry’s shift toward predictive maintenance, which can be further supported by external tools like mobile diagnostic apps. To stay ahead of emerging trends, consult resources such as auto repair industry forecasts for 2025. Embracing these electronic systems ensures that brake health is constantly optimized, reducing downtime and enhancing safety margins.

What innovative diagnostic tools can reveal the most elusive brake system problems before they escalate?

Technologies like infrared thermography enable experts to visualize uneven heat patterns across brake components, pinpointing issues such as caliper sticking or uneven pad wear. Coupling thermal imaging with dynamic testing—such as applying controlled braking forces—provides a comprehensive picture of system health. Modern diagnostic software, like those discussed in questions to ask your mechanic, supports precise troubleshooting, ensuring that even the most covert problems are addressed proactively. Leveraging such advanced diagnostics is a hallmark of expert-level maintenance, safeguarding vehicle reliability.

For those eager to deepen their understanding, exploring detailed maintenance checklists, such as the ultimate tune-up guide, can provide practical insights. Sharing knowledge within automotive communities not only elevates individual skills but also fosters a culture of safety and innovation. Remember, staying informed about cutting-edge diagnostic and maintenance strategies is key to maintaining peak brake system performance and ensuring roads remain safe for everyone.

Unveiling the Secrets of Precise Brake System Evaluation

In the realm of high-performance automotive maintenance, the ability to detect and diagnose hidden brake system anomalies is paramount. Traditional inspections often overlook subtle issues such as micro-cracks in rotors or microscopic caliper seize points that can compromise safety. Advanced diagnostic techniques, including ultrasonic testing and laser measurement, have emerged as essential tools for professionals aiming to preempt catastrophic failures.

Ultrasonic testing, for instance, employs high-frequency sound waves to penetrate deep into brake components. This method reveals internal flaws like cracks or delaminations that are invisible to the naked eye. Meanwhile, laser measurement tools provide nanometer precision in assessing rotor warping and pad thickness variations, enabling technicians to make informed decisions about component replacement or refurbishment.

Furthermore, integrating these diagnostics with electronic data acquisition systems allows for real-time monitoring and historical trend analysis. This integration facilitates predictive maintenance schedules that align with engineering principles, significantly reducing unexpected breakdowns and enhancing overall safety.

How do thermal imaging cameras revolutionize brake diagnostics for subtle caliper issues?

Thermal imaging cameras visualize heat distribution across brake components, providing insights into abnormal temperature patterns caused by sticking calipers or uneven pad wear. By capturing thermal anomalies during controlled braking tests, technicians can pinpoint specific problem zones with high accuracy. According to a study published in the Journal of Automotive Engineering (2022), thermal imaging has reduced diagnostic time by 35% while increasing detection sensitivity for hidden issues.

Incorporating these tools into routine diagnostics demands expertise, but their benefits in preventing accidents make them indispensable for professionals committed to excellence. Want to deepen your diagnostic skill set? Explore comprehensive training programs offered by industry leaders like Bosch or Snap-on, which focus on cutting-edge maintenance technologies.

Leveraging Material Science for Longevity and Safety

The evolution of brake materials directly influences diagnostic strategies. Modern semi-metallic and ceramic composites exhibit unique thermal and wear characteristics that require specialized testing protocols. For example, evaluating the coefficient of friction and heat capacity under simulated high-stress conditions can predict how materials will behave during emergency braking scenarios.

Recent advancements in nano-engineered friction materials, detailed in the Materials & Design journal, demonstrate enhanced resistance to thermal degradation and reduced wear rates. These innovations necessitate updated diagnostic benchmarks to ensure compatibility and performance. In practice, this means developing custom testing rigs that replicate real-world stresses, ensuring that brake components meet the highest safety standards.

Incorporate scientific insights into your maintenance routine to extend component lifespan and maximize safety margins. For professionals seeking to stay ahead, participating in ongoing research collaborations and industry symposiums is vital.

Beyond the Basics: Integrating Predictive Analytics in Brake System Management

As vehicles become increasingly integrated with electronic systems, harnessing data-driven approaches transforms maintenance from reactive to predictive. By analyzing sensor data—such as wear indicators, temperature logs, and pedal force patterns—technicians can forecast potential failures before they manifest.

Advanced algorithms utilizing machine learning models, as discussed in recent industry reports, can identify subtle trends indicative of impending issues. For example, a gradual increase in caliper temperature during routine tests may precede sticking, allowing preemptive intervention. This proactive strategy not only enhances safety but also optimizes maintenance costs and downtime.

Engaging with external diagnostic platforms and industry standards, such as the NHTSA guidelines, ensures your predictive models align with regulatory expectations. Embrace these technologies to elevate your diagnostic capabilities and safeguard your vehicle’s performance.

Interested in exploring these cutting-edge diagnostic tools? Consider specialized workshops and certification programs offered by automotive engineering societies. Staying abreast of technological innovations is essential for delivering the highest safety standards in brake system maintenance.

Innovative Approaches to Brake System Diagnostics That Experts Swear By

While traditional visual inspections serve as the foundation of brake maintenance, leveraging cutting-edge diagnostic tools like ultrasonic flaw detectors and laser measurement devices unlocks a new realm of precision. Ultrasonic testing penetrates deep into rotors and calipers, revealing micro-cracks and delaminations invisible to the naked eye, as highlighted in recent findings published by the American Society for Nondestructive Testing. Laser measurement tools, on the other hand, provide nanometer-level accuracy in assessing rotor warping and pad thickness, enabling technicians to preempt failures before they manifest. Integrating these technologies with real-time data analytics facilitates predictive maintenance strategies that vastly outperform reactive approaches.

Harnessing Material Science to Revolutionize Brake Longevity

Emerging nano-engineered friction materials and advanced composites redefine durability standards. These innovations, discussed extensively in the Materials & Design journal, exhibit superior heat dissipation, reduced wear, and enhanced resistance to thermal fatigue. To optimize safety, technicians must adopt testing protocols that evaluate these materials under simulated high-stress conditions, such as accelerated wear testing and thermal cycling. This scientific rigor ensures compatibility and maximizes lifespan, especially in high-performance or commercial vehicles where brake reliability is critical.

Why Predictive Analytics Is the Future of Brake Maintenance

Integrating sensor data with machine learning models transforms brake system management from reactive to predictive. Continuous monitoring of parameters like caliper temperature, pad wear metrics, and pedal force patterns, analyzed through sophisticated algorithms, can forecast imminent failures. For example, a gradual increase in caliper temperature during routine operation may indicate impending sticking, allowing preemptive intervention. Industry leaders like Bosch are pioneering these solutions, which align with NHTSA’s evolving safety standards. Embracing predictive analytics not only enhances safety but also drives cost efficiency by reducing unplanned downtime.

How can thermal imaging cameras detect hidden caliper issues with unmatched accuracy?

Thermal imaging cameras create detailed heat maps of brake components, revealing uneven temperature distributions caused by sticking calipers or uneven pad contact. During controlled braking tests, abnormal hotspots pinpoint specific problem areas, as evidenced in recent studies from the Journal of Automotive Engineering. This method accelerates diagnosis, reducing inspection time by up to 35%, according to industry research. For professionals aiming to elevate their diagnostic precision, investing in training from providers like Bosch or Snap-on offers invaluable expertise in thermal imaging technology. Want to stay at the forefront of brake diagnostics? Explore advanced training programs that hone these skills.

Material Science Frontiers and Their Impact on Brake Diagnostics

The shift toward nano-enhanced friction materials necessitates refined testing standards. Evaluating these materials’ friction coefficients, heat capacities, and wear rates under simulated high-stress conditions ensures their dependable performance. Recent breakthroughs documented in the Materials & Design journal underscore the importance of developing bespoke testing rigs that replicate real-world stresses, thus validating component resilience. Incorporating these scientific insights into routine diagnostics ensures that brake systems not only meet safety standards but exceed them, especially under demanding conditions like mountain descents or emergency stops.

Using Data-Driven Strategies to Predict Brake System Failures

The proliferation of electronic sensors in modern vehicles offers unprecedented opportunities for proactive maintenance. Analyzing sensor inputs—such as wear indicators, temperature logs, and pedal force data—through machine learning algorithms enables early detection of potential issues. For instance, a gradual increase in brake fluid temperature or pedal travel distance can forecast imminent failure, facilitating timely intervention. Industry experts recommend leveraging platforms like NHTSA’s safety data repositories and predictive maintenance software to enhance diagnostic accuracy. Want to unlock the full potential of your brake system management? Engage with industry-specific workshops and certification programs focused on data analytics in automotive maintenance.

Stay ahead in the field by exploring specialized training modules that focus on integrating electronic diagnostics with traditional inspection methods. Sharing insights and experiences within professional communities fosters continuous improvement and safety innovation, ultimately elevating standards across the industry.

Unlocking the Power of Precision Diagnostics in Brake Maintenance

Employing cutting-edge diagnostic tools like ultrasonic flaw detectors and thermal imaging cameras allows technicians to uncover micro-cracks, delaminations, and uneven heat distribution that are invisible to traditional inspections. This high-level approach minimizes unexpected failures and extends component lifespan, ensuring optimal safety and performance.

Material Innovations Shaping Brake Durability

Adopting nano-engineered friction materials and ceramic composites revolutionizes brake longevity. These advanced materials offer superior thermal stability, reduced wear, and enhanced resistance to thermal fatigue, which are critical for high-performance and commercial vehicles demanding consistent safety standards.

Harnessing Data Analytics to Preempt Brake Failures

Integrating sensor data with machine learning models enables predictive maintenance, allowing for early detection of issues such as caliper sticking, pad wear, or fluid degradation. This proactive strategy significantly reduces downtime and safety risks, aligning maintenance with engineering principles of reliability.

Curated Resources for the Automotive Professional

- American Society for Nondestructive Testing (ASNT) – Offers advanced training and certification in ultrasonic and thermal testing techniques, essential for expert-level diagnostics.

- Materials & Design Journal – Publishes the latest research on innovative brake materials and their engineering applications, guiding material selection and testing protocols.

- NHTSA Vehicle Safety Guidelines – Provides authoritative standards and best practices for preventive maintenance and safety compliance.

- Industry Conferences and Workshops – Participate in events hosted by automotive engineering societies for ongoing education on predictive analytics and emerging diagnostics.

Synthesizing Advanced Brake System Insights

Delving into expert strategies reveals that integrating sophisticated diagnostics, innovative materials, and data-driven maintenance transforms brake system reliability. For automotive professionals committed to safety and longevity, embracing these high-level insights and resources ensures mastery in brake system management. Engage with industry-leading training, contribute to ongoing research, and continuously refine your diagnostic approach to stay at the forefront of this critical field. Explore more about these techniques and resources to elevate your expertise and safeguard every journey.