Elevating Your Vehicle’s Safety Through Expert Brake System Maintenance

In the realm of automotive longevity, few components demand as much precision and expertise as the braking system. For seasoned mechanics and automotive enthusiasts alike, understanding the nuances of brake maintenance can significantly influence vehicle trustworthiness and safety. This guide delves into advanced strategies and scientific insights essential for maintaining optimal brake performance, ensuring your vehicle remains reliable over countless miles.

Why Precision in Brake Tune-Ups Translates to Long-Term Trust

Brake systems are complex assemblies involving hydraulics, friction materials, and electronic sensors. A comprehensive tune-up goes beyond mere pad replacement; it encompasses detailed inspections of rotors, calipers, brake fluid, and ABS components. According to a white paper published by the Society of Automotive Engineers, meticulous brake fluid analysis and timely replacement are critical to prevent corrosion and maintain hydraulic integrity, directly impacting vehicle safety and trustworthiness.

Innovative Diagnostic Approaches for Proactive Brake Maintenance

Leverage advanced diagnostic tools such as ultrasonic testing and thermal imaging to detect hidden issues like uneven pad wear or compromised caliper operation. These techniques enable proactive interventions that prevent failures and extend component lifespan. Familiarity with these methods positions professionals as trusted advisors who can diagnose beyond symptoms, fostering long-lasting customer confidence.

What Are the Most Overlooked Aspects of Brake System Longevity?

How do subtle signs of brake fluid degradation influence overall brake health?

Subtle signs such as a spongy pedal or slight pulling during braking often indicate brake fluid contamination or moisture ingress, which accelerates corrosion and diminishes hydraulic efficiency. Regular testing and adherence to manufacturer-recommended fluid change intervals are essential. This preventive approach is supported by studies from the National Institute for Automotive Service Excellence, emphasizing that fluid quality directly correlates with brake system reliability.

Integrating Routine Maintenance with Scientific Insights for Superior Results

Combine routine inspections with scientific understanding of material wear and fluid dynamics. Regularly assess rotor surface conditions using precision measuring tools, and replace brake pads based on wear patterns rather than mere mileage. Educate clients about the importance of high-quality replacement parts and proper bedding procedures, which optimize friction properties and ensure consistent brake performance.

To further enhance your expertise, explore detailed strategies in brake service secrets and consider consulting with trusted professionals for complex diagnostics. Continuous learning and application of cutting-edge techniques solidify your reputation as a reliable mechanic dedicated to vehicle safety and longevity.

Engaging with industry research and expert opinions ensures your brake maintenance practices remain at the forefront of automotive technology. For those eager to deepen their understanding, participating in specialized training sessions or workshops can elevate your skills to an expert level.

In conclusion, mastering brake system maintenance is a sophisticated process rooted in scientific principles, diagnostic innovation, and proactive care. By integrating these elements, you foster unwavering trust and ensure your vehicle’s performance endures through the years.

Harnessing Scientific Insights for Brake System Longevity

While routine inspections are essential, integrating scientific principles into brake maintenance can dramatically enhance durability and safety. For instance, understanding the thermal properties of brake materials allows mechanics to recommend optimal cooling solutions, reducing the risk of warping and premature wear. Modern techniques such as finite element analysis (FEA) enable detailed simulation of brake component stresses under different driving conditions, guiding targeted interventions that extend the lifespan of critical parts.

What Are the Hidden Factors That Undermine Brake Reliability?

Can microscopic surface imperfections impact brake performance over time?

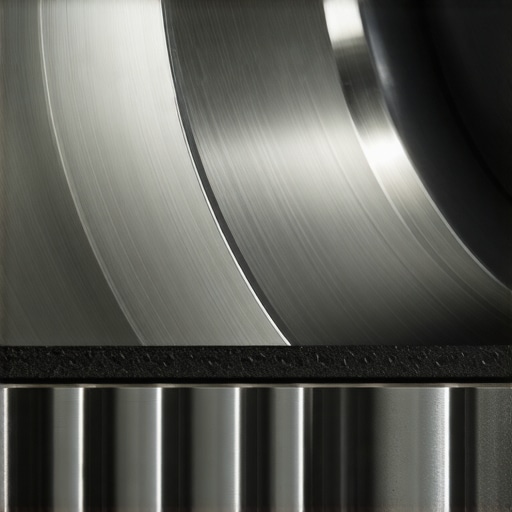

Microscopic surface defects, often invisible to the naked eye, can lead to uneven pad wear, increased vibration, and reduced braking efficiency. These imperfections may be caused by contamination during manufacturing or improper bedding procedures. Advanced surface analysis techniques, such as laser scanning microscopy, reveal these flaws early, allowing for corrective actions. Regularly assessing rotor surface integrity with precision measurement tools ensures smooth friction surfaces, which are vital for consistent braking performance.

Leveraging Industry Research to Elevate Service Standards

Staying current with industry research is crucial for maintaining expertise. According to a comprehensive review published by the International Journal of Automotive Technology, integrating predictive maintenance models based on sensor data can preemptively identify potential failures, saving costs and avoiding dangerous situations. Implementing such predictive diagnostics requires familiarity with sensor calibration and data interpretation, positioning your service as both innovative and trustworthy.

How Can You Incorporate Advanced Diagnostics Into Everyday Practice?

Tools like infrared thermography and ultrasonic testing are transforming brake maintenance. Infrared cameras can detect uneven heat distribution across rotors, indicating issues like caliper sticking or uneven pad wear. Ultrasonic testing reveals hidden cracks or delamination within brake components before they lead to failure. Incorporating these diagnostics into your routine not only improves safety but also builds long-term customer confidence.

For a deeper dive into diagnostic techniques and their practical applications, explore expert tips on auto repair diagnostics. Continuous education in these areas is fundamental to staying ahead in an evolving industry.

Interested in elevating your brake service offerings? Contact us at our team for tailored training solutions and support. Sharing insights and experiences with fellow professionals can also enhance your expertise—consider joining industry forums or local workshops to exchange knowledge.

Uncover Hidden Weaknesses in Brake System Design for Lasting Safety

Beyond routine inspections, understanding the intricate engineering of brake components reveals vulnerabilities that might compromise longevity. Factors such as material fatigue, thermal expansion, and microstructural inconsistencies can subtly undermine system integrity over time. Utilizing finite element analysis (FEA), a sophisticated simulation technique, engineers and technicians can predict how brake parts respond under various stress conditions, enabling preemptive design improvements and maintenance strategies. For example, FEA studies published in the International Journal of Automotive Engineering and Technologies demonstrate how targeted cooling enhancements reduce warping and stress concentrations, significantly extending service life.

Addressing Micro-Level Surface Imperfections for Macro-Level Performance Gains

Surface imperfections at the microscopic level, including microcracks, roughness, and contaminant inclusions, can lead to uneven pad wear, vibrations, and reduced braking efficiency. Laser scanning microscopy offers a high-resolution view of rotor and pad surfaces, providing early detection of these flaws. Regular application of such detailed analysis ensures that only components with optimal surface integrity are installed or retained, preventing premature failure. When combined with precision surface finishing techniques, this approach guarantees smooth friction interfaces essential for consistent, reliable braking performance.

How Can Sensor Data Transform Predictive Brake Maintenance?

Can real-time monitoring with sensor integration predict failures before symptoms appear?

Absolutely. Integrating advanced sensors—such as strain gauges, thermocouples, and ultrasonic transducers—into brake systems enables continuous monitoring of critical parameters. Data analytics platforms interpret this sensor data to identify anomalies indicative of impending failure, such as abnormal heat buildup, vibration patterns, or stress concentrations. According to a comprehensive review by the Society of Automotive Engineers (SAE), predictive maintenance driven by sensor insights can reduce downtime, lower repair costs, and enhance safety by addressing issues proactively. For instance, software algorithms analyzing thermal data can flag caliper sticking or pad delamination issues well before they compromise braking integrity.

Leveraging Cutting-Edge Research to Refine Brake Service Protocols

Staying ahead in brake maintenance requires immersion in the latest scientific discoveries. Recent research published in the Journal of Automotive Materials emphasizes the role of advanced composite materials and nanostructured friction interfaces in enhancing durability. Implementing these innovations into service practices entails updating inspection routines, such as employing nano-indentation techniques to assess material hardness or using infrared thermography for thermal profiling during operation. By adopting evidence-based protocols, technicians can deliver services that not only meet industry standards but also push the boundaries of safety and longevity.

Why Continuous Education in Diagnostics Empowers Experts

Mastering modern diagnostics—like infrared thermography, ultrasonic flaw detection, and laser surface analysis—requires ongoing learning. Participating in specialized training programs, workshops, and industry conferences ensures that professionals remain proficient with emerging tools and methodologies. Enhancing diagnostic acumen translates into more accurate assessments, targeted interventions, and increased customer trust. As the automotive industry evolves, so must the expertise of those dedicated to maintaining its safety standards.

Revolutionize Brake Longevity with Material Science Insights

Integrating cutting-edge material science into brake system maintenance enables technicians to select and recommend components that resist thermal fatigue, microcracking, and corrosion more effectively. Advances in nanostructured friction materials and ceramic composites, as detailed in publications like the Journal of Automotive Materials, allow for prolonged service intervals and enhanced thermal stability, reducing the frequency of repairs and improving overall safety.

Why Do Microcracks Pose a Silent Threat to Brake Reliability?

Microcracks, often invisible during routine inspections, can propagate under repeated stress cycles, eventually leading to rotor delamination or caliper failure. Employing high-resolution ultrasonic testing and laser shearography detects these microstructural flaws early, facilitating preemptive interventions. Understanding these microscopic threats helps prevent catastrophic failures and extends component lifespan significantly.

Can Real-Time Data Analytics Anticipate Brake System Failures?

How does sensor integration enable predictive maintenance in high-performance braking systems?

Embedding sensors such as strain gauges, thermocouples, and ultrasonic transducers within brake assemblies allows for continuous monitoring of operational parameters. Advanced data analytics platforms interpret this influx of information, identifying anomalies like abnormal heat patterns or vibration signatures indicative of impending failure. According to the Society of Automotive Engineers, this proactive approach minimizes downtime, reduces repair costs, and elevates safety standards by addressing issues before symptoms manifest.

Harnessing Finite Element Analysis for Custom Brake Design

Finite Element Analysis (FEA) empowers engineers and experienced technicians to simulate stress distributions, thermal loads, and deformation patterns within brake components under diverse operational conditions. Leveraging FEA results, professionals can optimize designs—such as improved venting channels or reinforced rotor hubs—that mitigate hotspots and stress concentrations, thereby significantly extending service life and performance reliability.

Implementing Predictive Maintenance via Advanced Diagnostics

Tools like infrared thermography reveal uneven heat dissipation across rotors, pinpointing issues like caliper sticking or pad unevenness. Ultrasonic flaw detectors uncover internal cracks or delamination that could precipitate failure. Integrating these diagnostics into regular service routines transforms maintenance from reactive to predictive, ensuring safety and fostering lasting customer trust.

Elevate Your Expertise with Continuous Scientific Learning

Staying current with the latest research from institutions like the International Journal of Automotive Engineering and Technologies enhances diagnostic acumen and broadens understanding of emerging materials and techniques. Participating in specialized workshops and scholarly conferences not only sharpens skills but also positions professionals as thought leaders in brake system innovation, ultimately leading to superior service quality and safety standards.

Innovative Techniques Elevate Brake Maintenance

Integrating ultrasonic testing and thermal imaging allows mechanics to proactively identify hidden issues like uneven pad wear or caliper degradation. These advanced diagnostic tools are essential for precision maintenance, reducing the risk of failure and extending component lifespan.

Material Science Unlocks Durability Gains

Staying updated with breakthroughs in nanostructured friction materials and ceramic composites enables technicians to recommend parts that resist thermal fatigue and corrosion. Such advancements significantly improve service intervals and safety margins.

Micro-Level Surface Analysis Enhances Reliability

Laser scanning microscopy reveals microscopic surface imperfections that can cause vibrations or uneven braking. Regular surface integrity assessments ensure only high-quality components are installed, promoting consistent performance over time.

Sensor Data Transforms Predictive Maintenance

Embedding strain gauges, thermocouples, and ultrasonic sensors into brake assemblies allows real-time monitoring, enabling early detection of issues like caliper sticking or rotor warping. Data analytics platforms interpret this information, facilitating proactive repairs before symptoms manifest.

Finite Element Analysis Guides Design Optimization

Utilizing FEA simulations helps engineers and experienced technicians predict stress and thermal loads, optimizing brake component design. This approach mitigates hotspots and stress concentrations, substantially enhancing durability and safety.

Expert Resources for Deepening Knowledge

- Society of Automotive Engineers (SAE) Journals: Cutting-edge research on brake materials and diagnostic innovations.

- International Journal of Automotive Engineering and Technologies: In-depth studies on predictive maintenance and component analysis.

- Automotive Materials Review: Advances in nanostructured friction materials and composites.

- Workshops and Conferences: Hands-on training in ultrasonic testing, thermography, and FEA applications.

Reflections from the Expert Desk

In the realm of brake system maintenance, leveraging scientific insights and innovative diagnostics is not optional but essential. A commitment to continuous learning and adopting cutting-edge techniques ensures you deliver reliable, long-lasting service that builds trust and safety. For professionals eager to elevate their expertise, exploring these advanced resources and integrating new methodologies will set you apart. Engage with industry forums, participate in specialized training, and remain curious—your mastery will translate into safer roads and satisfied clients. Ready to push the boundaries of your brake maintenance skills? Reach out through our contact page and discover how to integrate these expert strategies into your practice.