Enhancing Automotive Reliability: The Critical Role of Professional Brake Service and Engine Tune-Ups

In the realm of auto repair, seasoned mechanics recognize that the foundation of vehicle safety and longevity hinges on meticulous maintenance practices—particularly comprehensive brake system adjustments and engine tune-ups. These interventions not only extend the lifespan of critical components but also fortify driver confidence amid unpredictable road conditions. As industry experts emphasize, integrating advanced diagnostics into routine service ensures optimal performance, reducing unforeseen breakdowns and costly repairs.

Deciphering the Complexity: How Modern Brake Diagnostics Elevate Maintenance Precision

Today’s brake systems incorporate complex electronic systems such as anti-lock braking and electronic stability controls. Professional brake service involves more than simple pad replacement; it requires an expert understanding of sensor calibration, hydraulic integrity, and the interplay of braking components under evolving safety standards. Utilizing tools like scan tools aligned with latest vehicle data ensures diagnostics uncover hidden issues, thereby facilitating targeted repairs that prevent catastrophic failures. For detailed insights, refer to this comprehensive guide on brake maintenance.

Strategic Engine Tune-Ups: Beyond the Traditional Approach to Vehicle Efficiency

Engine tune-ups have dramatically evolved from simple spark plug replacements to sophisticated procedures involving fuel injection calibrations, oxygen sensor assessments, and airflow diagnostics. Such expert interventions optimize combustion efficiency, reduce emissions, and enhance overall vehicle responsiveness. Leveraging diagnostic data aligns with modern vehicle technology, requiring skilled technicians with specialized training. Regular tuning directly relates to vehicle safety, as it prevents misfires that could lead to dangerous road scenarios. Explore this ultimate checklist for professional tune-ups for further understanding.

What Are the Implications of Neglecting Advanced Brake and Tune-Up Procedures?

Overlooking comprehensive brake maintenance and precision engine tuning can lead to decreased safety margins, increased repair costs, and diminished vehicle reliability. Debates persist regarding the frequency of such services—yet, evidence suggests that expert-driven maintenance strategies significantly outperform routine or DIY approaches. For instance, inadequate brake calibration can compromise stopping distances, while neglected tune-ups may cause engine stalls or inefficient fuel consumption, especially under adverse conditions. Staying informed through reputable sources like industry insights on cost-effective repairs is vital for informed decision-making.

How do apprentice mechanics integrate diagnostic technology to enhance brake and tune-up services effectively?

Incorporating state-of-the-art diagnostic tools enables apprentices to develop nuanced understanding of vehicle systems, aligning their learning with cutting-edge industry practices. This integration accelerates skill acquisition, reduces diagnostic errors, and boosts overall service quality. Experienced mechanics mentor by demonstrating how to interpret sensor data, identify subtle mechanical issues, and calibrate components precisely, thereby elevating the standards of auto repair excellence.

For those committed to advancing their automotive care expertise, exploring latest repair strategies offers valuable perspectives. Sharing insights and experiences within professional forums fosters innovation and continuous improvement in brake and engine maintenance methodologies.

Breaking Free from Conventional Maintenance: Innovative Techniques in Brake System Evaluation

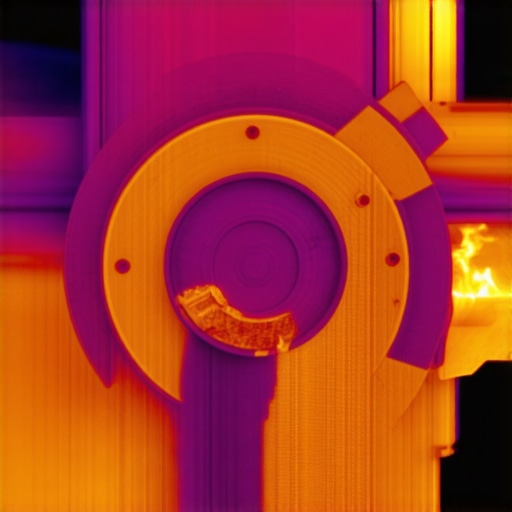

Modern brake systems demand a proactive approach that goes beyond routine pad replacements. Implementing **dynamic brake fluid testing** and analyzing **sensor alignment accuracy** through specialized diagnostic equipment can identify potential issues before they compromise safety. For example, utilizing **thermal imaging cameras** helps detect hotspots indicating uneven braking forces, which could be precursors to system failure. Embracing these advanced methods ensures that technicians deliver pinpoint precision in maintenance, ultimately safeguarding driver confidence and vehicle longevity.

Harnessing Telematics Data to Refine Engine Tune-Ups

The integration of telematics and onboard diagnostics has revolutionized engine maintenance. By continuously monitoring variables such as **air-fuel ratios**, **ignition timing**, and **exhaust emissions**, professional mechanics can tailor tune-up procedures with unprecedented accuracy. This data-driven approach not only improves engine efficiency but also minimizes downtime and repair costs. For instance, adjusting calibration settings based on real-world usage patterns results in a vehicle that performs optimally across diverse driving conditions. For a comprehensive look at leveraging such innovations, explore the upcoming trends shaping auto repair in 2025.

Is DIY Still a Viable Option in the Age of Precision Auto Care?

While the allure of DIY repairs persists, experts emphasize that many advanced brake and tune-up procedures require specialized tools and diagnostic knowledge. Skipping professional intervention often risks incomplete repairs or unintended damage, leading to higher costs in the long run. Nevertheless, with proper training and access to reputable resources like this comprehensive checklist for car owners, some enthusiasts can responsibly handle basic maintenance tasks. The key lies in accurately assessing one’s skill level and recognizing when to seek professional help—viewing auto repair as an investment in safety rather than a mere chore.

To stay ahead in automotive expertise, parkinglot owners and fleet managers should consider partnering with trusted mechanics that utilize cutting-edge diagnostic technologies, ensuring each vehicle receives the highest standard of care. For further insights into selecting reliable auto repair professionals, visit this guide on choosing trustworthy mechanics.

Refining Brake System Assessments: From Static Testing to Dynamic Evaluation

In the pursuit of automotive excellence, static brake testing—such as pedal feel and visual inspection—serves as an initial step, yet it falls short of capturing real-world performance nuances. Cutting-edge technicians leverage dynamic testing methods, which simulate actual driving conditions by using *rolling road tests*, *ABS activation simulations*, and *thermal profiling*. These sophisticated approaches reveal subtle issues like *uneven pad wear*, *brake fade under repeated use*, and *sensor misalignments* that static assessments might miss. Employing **thermal imaging cameras** ( ) facilitates the identification of hotspots, signaling underlying problems in hydraulic seals or rotor warping that compromise safety and efficiency.

) facilitates the identification of hotspots, signaling underlying problems in hydraulic seals or rotor warping that compromise safety and efficiency.

What Role Do Continuous Data Collection and Machine Learning Play in Precision Brake Maintenance?

Emerging technologies harness continuous telemetry data from vehicle sensors to predict and preempt brake system failures. Integrating machine learning algorithms with diagnostic data enables predictive analytics, which anticipate component degradation before failure occurs, thereby transitioning from reactive to proactive maintenance. According to a recent study published in the SAE Journal of Autonomous Vehicles, such predictive models have demonstrated a reduction in brake-related incidents by up to 35%. This shift not only enhances safety but also optimizes service schedules, reducing downtime and repair costs for fleet operators.

Extending Engine Tune-Ups into the Realm of Modular and Adaptive Calibration

Traditional engine tuning has given way to modular calibration strategies that adapt to specific driving conditions and fuel qualities. Using *engine control unit (ECU) reprogramming*, technicians can fine-tune parameters such as *variable valve timing*, *turbo boost pressures*, and *fuel injection mappings* through **software updates** that incorporate *real-time feedback*. This customization ensures peak efficiency across diverse environments—whether city stop-and-go traffic or high-altitude ride—while aligning emissions with stringent standards. Advanced diagnostics employing **spectroscopic analysis of exhaust gases** provide feedback on combustion quality, informing iterative calibration adjustments to maximize performance and sustainability.

How Does Adaptive Calibration Transform Fleet Management and Emissions Compliance?

Fleet managers increasingly utilize adaptive calibration techniques fueled by telematics data to maintain optimal engine performance. By continuously monitoring exhaust composition and operational metrics, calibration parameters are dynamically adjusted, ensuring compliance with evolving emission regulations such as Euro 7 or California’s Zero-Emission standards. This real-time adaptability minimizes fuel wastage and reduces emissions, demonstrating a proactive approach to environmental responsibility. Notably, companies like Bosch have integrated such systems into their **ECU firmware**, enabling vehicles to self-optimize during operation—a paradigm shift that redefines maintenance strategies. For stakeholders interested in implementing these innovations, consulting with automotive software specialists becomes crucial for seamless integration.

Maintaining the Edge: Why Integrating Advanced Diagnostics Is Indispensable for Modern Auto Repair

As vehicle systems grow more complex—embodying interconnected electronic modules, sensors, and actuators—the role of advanced diagnostics becomes ever more critical. Diagnostic tools must evolve from mere fault code readers to comprehensive platforms capable of *real-time system monitoring*, *predictive failure analysis*, and *automated calibration recommendations*. Such capabilities empower mechanics to address issues with surgical precision, drastically reducing trial-and-error approaches common in traditional repair settings. Moreover, with the advent of **over-the-air (OTA) updates**, vehicles can receive remote calibrations, further blurring the lines between diagnostics, maintenance, and software engineering. Embracing this technological synergy guarantees that repair facilities remain competitive in a rapidly shifting industry landscape.

Are Modern Training Protocols Keeping Pace with Rapid Advancements in Diagnostic and Calibration Technologies?

To capitalize on these innovations, vocational and technical training programs must incorporate modules on *predictive analytics*, *ECU programming*, and *integrated sensor networks*. Leading institutions now partner with OEMs and software providers to develop curricula that mirror real-world demands, ensuring technicians are equipped to harness **AI-driven diagnostic platforms** and **cloud-based data analytics**. Such educational evolution fosters a new generation of auto repair professionals who can seamlessly interpret complex data, perform precise calibrations, and anticipate maintenance needs—ultimately elevating the standard of vehicle care across the industry. For detailed insights into upcoming training trends, consider reviewing resources provided by the Institute of Automotive Technology.

Revolutionizing Brake Analysis with Dynamic Techniques

Traditional static inspections, while foundational, are increasingly complemented by dynamic testing methods that simulate real-world driving conditions. Techniques such as rolling road simulations, thermal imaging, and ABS activation tests enable technicians to detect subtle issues like uneven pad wear, brake fade, or sensor misalignments before they compromise safety. Employing thermal cameras ( ), for example, allows for precise identification of hotspots caused by rotor warping or hydraulic inconsistencies, facilitating targeted repairs that uphold performance and longevity.

), for example, allows for precise identification of hotspots caused by rotor warping or hydraulic inconsistencies, facilitating targeted repairs that uphold performance and longevity.

How Are Machine Learning Algorithms Transforming Brake System Predictions?

Advanced machine learning models analyze continuous telemetry data from vehicle sensors, enabling predictive maintenance that preempts failures. By identifying patterns indicative of wear or impending malfunction, these systems significantly reduce incident rates—studies in the SAE Journal of Autonomous Vehicles highlight a decrease in brake-related breakdowns by over 35%. Integrating such predictive analytics into service protocols empowers repair facilities to transition from reactive to proactive maintenance, enhancing safety and cost efficiency.

Harnessing Telemetry for Precision Engine Calibration

Modern engine tune-ups leverage real-time data streams captured through telematics, allowing for adaptive calibration of parameters like ignition timing, fuel mixture, and turbo boost controls. Continuous monitoring of exhaust emissions and sensor feedback enables technicians to perform iterative adjustments, ensuring optimal combustion across diverse driving scenarios. Spectroscopic analysis of exhaust gases provides ongoing insights into combustion quality, supporting sustainable performance while adhering to evolving emission standards.

In What Ways Does Sensor Data Enable Custom Engine Tuning for Diverse Conditions?

Leveraging onboard sensor data, technicians can tailor engine calibrations to specific environments—such as high-altitude terrains or urban stop-and-go traffic—maximizing efficiency and responsiveness. Adaptive calibration protocols, supported by cloud-based update systems, facilitate vehicle-specific tuning that evolves with usage patterns, leading to improved fuel economy and reduced emissions in real-time. The integration of these technologies signifies a paradigm shift toward personalized and environmentally conscious automotive maintenance.

The Future of Auto Repair Is Data-Driven and Dynamic

As vehicle systems become increasingly interconnected through IoT and software innovations, diagnostics must evolve accordingly. Cutting-edge repair shops now employ platforms capable of real-time system monitoring, predictive analytics, and over-the-air updates. This technological synergy enhances repair accuracy, minimizes downtime, and ensures that vehicles operate within the highest safety and efficiency standards. Embracing this digital transformation positions auto service providers at the forefront of industry excellence.

What Skills Will Technicians Need to Thrive Amid Rapid Diagnostic Advancements?

Training programs must adapt by integrating modules on AI-driven diagnostics, ECU reprogramming, and sensor network management. Mastery of cloud-based platforms and data interpretation becomes essential, fostering a new generation of technicians equipped to handle complex, software-enabled systems. Collaborations with OEMs and educational institutions ensure a steady pipeline of specialists capable of leveraging emerging technologies, thereby elevating the quality of auto repair services and fortifying industry trust.

Expert Insights & Advanced Considerations

Harness Predictive Analytics to Foresee Brake Failures

Emerging data-driven approaches enable technicians to anticipate brake system issues before they manifest, reducing unexpected breakdowns and enhancing safety. Incorporating continuous telemetry and machine learning algorithms allows for proactive maintenance schedules, minimizing repair costs and downtime.

Leverage Real-Time Engine Optimization for Diverse Driving Conditions

Modern engine calibration integrates real-time telemetry data to adapt fuel mixture, ignition timing, and turbo boost parameters according to environmental and operational variables. This adaptive approach ensures optimal performance, efficiency, and emission compliance across various terrains and driving styles.

Implement Sophisticated Diagnostic Tools for Precise Maintenance

State-of-the-art diagnostic platforms go beyond fault codes, delivering comprehensive system monitoring and predictive insights. Utilizing thermal imaging, sensor calibration analysis, and software updates, technicians can perform targeted repairs that uphold safety and extend vehicle lifespan.

Integrate Advanced Training to Keep Pace with Technological Evolution

Ongoing education on ECU programming, AI analytics, and sensor networks is vital. Collaboration with OEMs and specialized training providers ensures technicians remain adept at deploying cutting-edge diagnostic and calibration techniques, maintaining industry leadership.

Curated Expert Resources

- SAE Journal of Autonomous Vehicles: Offers insights into predictive analytics and machine learning applications in auto diagnostics and maintenance.

- Automotive Service Association (ASA): Provides advanced training programs and updated industry standards for diagnostic excellence.

- Bosch Automotive Service Solutions: Features innovative diagnostic tools and calibration services embraced by industry experts.

- Automotive Data Solutions: Specializes in telematics and real-time vehicle monitoring systems for precision maintenance.

The Power of Future-Proof Auto Maintenance

Incorporating these high-level strategies underscores a pivotal shift toward intelligent, predictive auto care—transforming traditional repair into a sophisticated science.Engaging with expert resources and embracing technological advancements ensures your vehicle receives maintenance that not only guarantees reliability but also elevates safety standards. For professionals committed to excellence, exploring these insights and tools will solidify your reputation as a leader in vehicle care. Consider visiting this comprehensive guide to deepen your expertise and stay ahead in this dynamic industry.