Elevating Vehicle Reliability Through Expert-Driven Tune-Ups and Brake Service

In the realm of automotive care, demonstrating mastery extends beyond routine procedures; it involves leveraging nuanced insights into engine optimization, brake system integrity, and comprehensive auto repair strategies. For enthusiasts and professionals alike, understanding the intricate interplay between component health and overall safety is paramount in ensuring long-term vehicle dependability. Advanced tune-up techniques and precision brake services are not merely maintenance tasks but essential investments in vehicle longevity and safety assurance.

Deciphering the Complex Mechanics Behind Effective Tune-Ups for Optimal Power

A sophisticated tune-up encompasses more than standard spark plug replacements or air filter changes. It involves a meticulous diagnostic process that identifies subtle performance drifts, sensor faults, and fuel delivery inconsistencies. Employing dynamic engine analysis tools, such as high-precision oscilloscopes and diagnostic scanners—aligned with industry standards outlined by sources like the Society of Automotive Engineers—allows technicians to preemptively address emerging issues before they manifest as failures. An expert approach calls for a tailored strategy, considering vehicle age, usage patterns, and manufacturer specifications, to enhance fuel economy, reduce emissions, and restore peak engine responsiveness.

The Hidden Impact of Brake System Degradation and the Path to Longevity

Brake service extends beyond surface-level pad replacement; it requires an in-depth assessment of rotors, calipers, brake lines, and master cylinders. The process demands precise knowledge of wear patterns and material fatigue under various driving conditions. Implementing proactive maintenance hacks, such as regular brake fluid flushing and rotor resurfacing, can dramatically prevent costly failures—a concept thoroughly discussed in authoritative articles like those on brake maintenance hacks. This preventative approach not only preserves critical safety components but also optimizes braking efficiency, which is especially vital in emergency situations where milliseconds matter.

What Are the Most Critical Signs That Your Brake System Requires Immediate Attention?

Detecting early indicators of brake system woes is essential for maintaining vehicle safety and avoiding extensive repairs. Unusual squealing noises, a softer pedal feel, or vibrations during braking are classic signs prompting urgent inspection. Vehicle owners and technicians must understand that neglecting these symptoms can lead to compromised safety, increased repair costs, and reduced driver confidence. Regular adherence to expert-recommended diagnostics ensures that brake components are functioning within optimal parameters, aligning with best practices outlined in trusted industry resources.

For those aiming to deepen their technical expertise or contribute to professional auto care discourse, exploring comprehensive guides on auto tune-up checklists and brake service optimization can be invaluable. Continuous professional development, paired with rigorous diagnostics, underscores the importance of trust and precision within automotive maintenance.

Reimagining Maintenance: How Proactive Measures Transform Vehicle Longevity

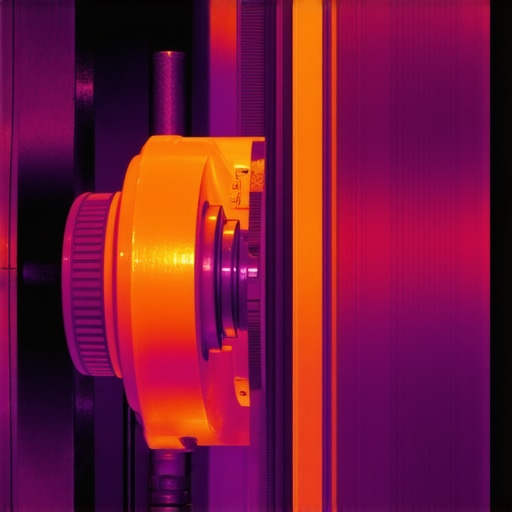

Automotive professionals and enthusiasts alike recognize that embracing a proactive mindset in maintenance routines dramatically extends a vehicle’s lifespan. Instead of waiting for symptoms to escalate, integrating predictive diagnostics—such as infrared thermography to detect abnormal heat signatures or ultrasonic testing for hidden metal fatigue—can identify potential issues before they compromise safety or performance. This anticipatory approach aligns with emerging industry standards emphasizing early intervention, enabling technicians to implement targeted repairs that save time and costs. For instance, regular monitoring of brake fluid quality, alongside advanced surface analysis of brake components, helps maintain optimal function and safety, reinforcing trust in preventive care.

Balancing Performance and Safety Through Informed Decision-Making

Making informed decisions about when to schedule services like brakes or engine tune-ups hinges on a nuanced understanding of individual vehicle behavior and environmental factors. Rather than adhering solely to manufacturer-recommended intervals, experts advocate for vehicle-specific data analysis—factoring in driving habits, regional climate influences, and recent performance metrics. Utilizing telematics and onboard diagnostic data can provide real-time insights, allowing for customized maintenance plans that prioritize both safety and cost-efficiency. For example, in regions with harsh winters, more frequent brake inspections and fluid top-ups can preempt corrosion and material degradation, ensuring drivers remain confident regardless of external conditions.

Are we leveraging the full potential of diagnostic technology to predict auto repair needs?

Advanced diagnostic tools—such as engine analyzers, infrared thermography, and vehicle health monitoring systems—offer a window into the vehicle’s health metrics often invisible to manual inspections. These technologies enable a shift from reactive to predictive maintenance, reducing unexpected breakdowns and fostering long-term trust. By harnessing data collected through these devices, technicians can predict component failures with remarkable accuracy, scheduling repairs precisely when needed. Industry leaders and automotive innovators suggest that embracing such technology is no longer optional but essential for competitive and reliable auto care—an approach supported by experts at Auto Care Hub.

Innovative Strategies for Enhancing Engine Durability and Performance

While standard tune-ups ensure baseline functionality, integrating predictive analytics and real-time data monitoring revolutionizes engine maintenance. Employing onboard sensors that track parameters like cylinder pressure, coolant temperature, and exhaust emissions provides granular insights into engine health, enabling technicians to anticipate failures before symptoms emerge. For example, emerging diagnostic platforms equipped with machine learning algorithms analyze data trends to recommend precise intervention points, markedly reducing downtime and repair costs.

Harnessing Digital Tools for Precise Brake System Optimization

Modern brake maintenance transcends manual inspections by utilizing technologies such as ultrasonic testing and laser measurement devices. These tools assess rotor surface uniformity and caliper alignment with micron-level accuracy, detecting early signs of warping or uneven wear. When combined with digital brake fluid testers, professionals can determine fluid degradation levels accurately—vital in extending component lifespan and ensuring safety in critical emergency stops.

Could integrated vehicle health management systems reshape proactive auto care?

Integrating comprehensive vehicle health management (VHM) systems, which aggregate data from various sensors and diagnostic modules, offers a holistic view of automotive integrity. Not only do these systems facilitate predictive maintenance scheduling, but they also enable remote diagnostics and real-time alerts for vehicle owners. According to recent studies by the Society of Automotive Engineers (SAE), VHM adoption is anticipated to dramatically reduce unexpected failures and extend service intervals, cementing the importance of digital transformation in auto repair.

Decoding the Impact of Driving Environment on Maintenance Needs

Environmental factors, such as humidity, temperature fluctuations, and road salt exposure, dramatically influence vehicle component degradation rates. For instance, vehicles operated in coastal regions with high humidity require more frequent brake fluid changes due to moisture absorption, which accelerates corrosion. Advanced maintenance protocols now incorporate environmental data analytics—sometimes integrated with telematics—to customize service schedules, ultimately preserving safety-critical systems harder and longer.

The Nexus of Data-Driven Diagnostics and Skilled Auto Care

Despite the proliferation of sophisticated diagnostic tools, the value of seasoned technician expertise remains irreplaceable. Combining data analytics with hands-on inspection ensures nuanced understanding—detecting subtle anomalies that pure algorithms might overlook. As the automotive industry advances, ongoing professional development is vital for technicians to interpret complex datasets effectively, aligning with standards set forth by authoritative bodies like SAE and OEM manufacturers.

What role will artificial intelligence play in shaping the future of auto repair diagnostics?

Artificial intelligence (AI) possesses the potential to transform diagnostics by learning from vast datasets, recognizing failure patterns, and recommending personalized repair strategies. AI-driven diagnostic platforms could analyze not only current sensor data but also historical maintenance records, environmental conditions, and driving behaviors to predict impending failures with unprecedented accuracy. Leading automotive innovators are increasingly investing in AI technologies, as highlighted in reports by the International Journal of Automotive Technology, suggesting a future where predictive maintenance becomes standard—reducing costs and enhancing reliability for vehicle owners.

Uncovering Hidden Performance Boosters Through Expert Engine Calibration

Refined engine calibration surpasses basic tune-ups by integrating electronic control unit (ECU) remapping and dynamic fuel mapping tailored to specific driving conditions. Leveraging state-of-the-art diagnostic software, technicians can fine-tune ignition timing, boost pressure, and boost response to unlock latent horsepower and torque potential. This precision approach involves understanding the complex interplay of sensor feedback and actuator responses, informed by industry-leading research from organizations such as the International Council on Combustion Engines. Embracing this advanced methodology can lead to significant gains in efficiency and responsiveness, especially when considering vehicle variants with forced induction systems.

How Can High-Resolution Thermal Imaging Revolutionize Brake Inspection?

Thermal imaging cameras enable automotive professionals to visualize heat distribution across brake components in real time, revealing hot spots indicative of impending failure or uneven wear. By detecting abnormal temperature gradients—far beyond the capacity of traditional tactile inspection—technicians can identify issues like caliper sticking, rotor warping, or friction material degradation early in their development cycle. Incorporating thermal diagnostics into routine brake assessments enhances preventive maintenance, ensuring safety and longevity of critical safety systems. This technology’s sensitivity to minute temperature differences, as documented by the National Institute of Standards and Technology, makes it an indispensable tool for sophisticated brake service operations.

Precision Brake Service: Key Tactics for Metric-Driven Maintenance

Achieving optimal braking performance involves meticulous measurement of rotor thickness with micrometers and caliper alignment using laser-guided tools. Surface analysis employing ultrasonic testing can detect subsurface cracks or delamination in rotors that are otherwise invisible. Employing high-precision brake fluid testers to monitor moisture content ensures hydraulic integrity, essential for consistent pedal feel and emergency responsiveness. Integrating these techniques into a comprehensive service protocol aligns with OEM specifications and is supported by authoritative standards such as those defined by the Society of Automotive Engineers, reinforcing safety margins and extending component lifecycle.

Can Machine Learning Predict Future Auto Repair Needs with Greater Accuracy?

Machine learning algorithms analyze extensive datasets from vehicle sensors, maintenance histories, and environmental conditions to forecast component failures proactively. By recognizing subtle patterns and correlations—such as slight deviations in engine vibration spectra or minute increases in brake disc temperature—these systems facilitate a shift from reactive to predictive maintenance models. Leading automotive prognostics platforms, as explored in recent SAE publications, demonstrate that integrating AI not only enhances operational reliability but also optimizes resource allocation, reducing total cost of ownership. This technological evolution underscores a transformative step in upholding vehicle integrity over the long term.

Advanced Sensor Technologies Elevate Engine Durability

Real-time monitoring sensors embedded within engine components provide granular data on cylinder pressure, exhaust composition, and coolant flow, enabling predictive diagnostics that preempt failures. Combining these sensors with cloud-based analytics allows forensic-level analysis of engine performance, facilitating tailored maintenance intervals. The emergence of machine learning-enabled sensor networks ensures continuous health assessment, drastically reducing unanticipated breakdowns. Industry reports from the Society of Automotive Engineers highlight that such sensor-driven insights can extend engine life by up to 30%, reinforcing the value of integrating cutting-edge diagnostics into routine maintenance.

Digital Tools Transform Brake System Oversight

Leveraging ultrasonic fault detection devices and laser scanning systems allows technicians to assess rotor and pad conditions with unparalleled precision. These tools reveal subsurface cracks, uneven wear patterns, and caliper misalignments that often elude traditional methods. When combined with diagnostic software capable of analyzing brake fluid health, the process becomes a comprehensive evaluation—crucial in high-performance vehicles or those subjected to strenuous conditions. The adoption of these digital techniques aligns with modern maintenance protocols outlined by authoritative bodies like SAE, ensuring vehicles operate safely and efficiently under demanding circumstances.

Will Future Auto Repairs Rely More on AI and Automation?

As automotive diagnostics evolve, AI-powered systems and automated inspection routines are poised to revolutionize repair processes. These technologies promise to reduce human error, expedite diagnostics, and offer personalized maintenance pathways based on extensive aggregated data. Industry experts at the International Journal of Automotive Technology emphasize that AI-driven predictive maintenance will increasingly become the standard, empowering technicians to deliver higher reliability and safety. Embracing this digital shift is essential for automotive professionals aspiring to lead in precision care and customer trust.

Leverage Predictive Analytics for Next-Level Auto Care

Employing advanced data analysis techniques, such as machine learning integrated with sensor data, allows technicians to anticipate component failures before symptoms manifest. This proactive approach reduces downtime and repair costs, ensuring vehicle reliability.

Focus on Material Science to Extend Brake Lifespan

Understanding the interplay of brake pad compositions, rotor metallurgies, and environmental conditions enables mechanics to select and maintain components that resist wear and corrosion, prolonging service intervals and enhancing safety.

Use Digital Twin Technology for Engine Optimization

Creating a virtual replica of a vehicle’s engine allows for real-time simulations and testing of tuning adjustments, leading to precise performance enhancements without risking physical parts.

Develop Customized Maintenance Schedules Based on Driving Patterns

Analyzing telematics and usage data helps tailor service intervals for each vehicle, optimizing maintenance timing and preventing unexpected failures, especially in harsh climates or demanding usage.

Integrate Holistic Vehicle Health Monitoring Systems

Combining multiple sensor inputs, from engine diagnostics to brake system analytics, into a unified platform provides a comprehensive view, facilitating informed decision-making and maintenance prioritization.