Elevating Vehicle Safety Through Expert Brake Maintenance and Precision Tune-Ups

In the realm of automotive care, few aspects are as critical to long-term vehicle safety as meticulous brake service and comprehensive tune-up strategies. As an industry expert, I recognize that optimizing these elements not only enhances safety but also extends the lifespan of essential components, thereby reducing costly repairs and downtime. This article delves into the nuanced approaches that professional technicians employ to ensure your vehicle remains reliable under diverse driving conditions.

Unlocking the Complexities of Brake System Longevity

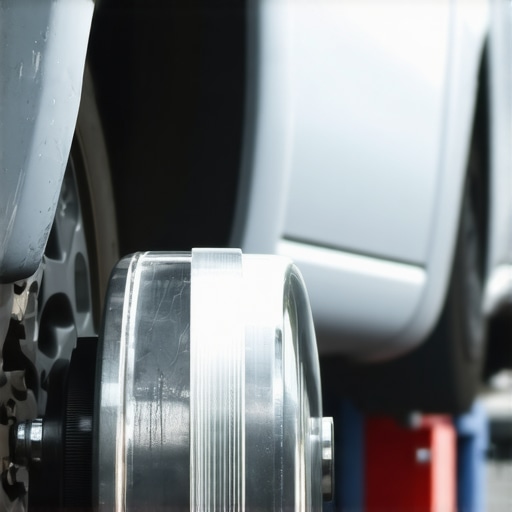

Achieving durable brake performance involves more than routine pad replacements. Advanced brake service encompasses analyzing rotor wear patterns, assessing caliper functionality, and checking hydraulic fluid integrity. For instance, selecting high-quality brake pads aligned with your driving profile can significantly influence stopping power and noise reduction. Moreover, incorporating anti-corrosion treatments and precise rotor resurfacing during service can prevent uneven wear, which is often overlooked by casual maintenance routines.

Innovative Approaches to Tune-Up Protocols for Optimal Engine Performance

Modern tune-up strategies transcend basic spark plug replacements. They involve detailed diagnostics of fuel injectors, ignition timing, and sensor calibrations to ensure seamless engine operation. Utilizing scan tools and data analysis, seasoned technicians can identify underlying issues like misfires or sensor anomalies before they escalate. This proactive approach safeguards against engine degradation, maintains fuel efficiency, and ensures compliance with emissions standards, thus reinforcing long-term vehicle trustworthiness.

What Are the Signs That Your Brake System Needs Professional Intervention

Detecting early signs of brake deterioration is vital for safety. Unusual squealing noises, a soft pedal feel, or vibrations during braking should prompt immediate inspection. More subtle indicators include a burning smell or increased stopping distances. Regularly consulting expert resources, such as when to know you need brake service now, can help vehicle owners recognize these symptoms early and prevent costly failures.

How Can Advanced Brake Fluid Testing Improve Vehicle Safety and Reliability?

Brake fluid deteriorates over time, absorbing moisture that compromises hydraulic pressure and leads to brake failure. Advanced testing techniques, such as moisture content analysis, enable precise assessments of fluid condition. Replacing or flushing brake fluid at strategic intervals, as recommended by industry standards, can drastically improve braking responsiveness and prevent corrosion within the system. This proactive maintenance exemplifies the importance of integrating scientific insights into routine service for long-term safety.

For a deeper understanding of comprehensive auto repair practices, explore the ultimate tune-up checklist for every car owner. Sharing your expertise and experiences with trusted mechanics can further enhance your vehicle’s reliability. Remember, maintaining a vehicle’s safety systems is an ongoing process requiring expert knowledge, precision, and strategic planning—investing in professional brake and tune-up services today ensures confident driving tomorrow.

Elevate Your Car’s Reliability with Advanced Maintenance Techniques

Beyond basic service routines, implementing sophisticated diagnostic tools and targeted maintenance protocols can significantly enhance your vehicle’s safety and performance. For example, utilizing ultrasonic testing to detect hidden rotor cracks or caliper issues allows technicians to address problems before they manifest as costly failures. These proactive measures are crucial for maintaining optimal brake system health, especially in high-mileage or demanding driving conditions.

Why Ignoring Subtle Signs Can Lead to Major Failures

Many drivers overlook minor symptoms such as slight pulling during braking, inconsistent pedal feel, or faint vibrations. However, these signals often indicate underlying issues like uneven rotor wear, contaminated brake fluid, or caliper sticking. Recognizing and addressing these early warning signs through expert inspection can prevent dangerous situations and extend the lifespan of your braking system. Regularly consulting trusted resources, like when to know you need brake service now, empowers vehicle owners to make informed maintenance decisions.

Are Your Brake Components Truly Up to the Challenge?

Understanding the wear patterns and material compatibility of brake components is essential for long-term safety. High-performance brake pads, for instance, can provide superior heat dissipation and noise reduction if matched correctly to your driving style. Similarly, advanced rotor resurfacing techniques can eliminate surface irregularities without removing excessive material, maintaining structural integrity. Staying ahead with these nuanced practices ensures your brakes can handle sudden stops and prolonged use, reducing the risk of catastrophic failure.

For more expert insights into maximizing your vehicle’s safety and longevity, explore brake service secrets. Sharing your experiences with trusted mechanics and asking the right questions—such as those outlined in getting the most from your mechanic—can elevate your understanding and foster a partnership built on trust.

Investing in professional brake and tune-up services today not only ensures safer roads but also preserves your vehicle’s value and performance over time. Remember, the road to reliable auto care involves continuous learning, strategic maintenance, and expert intervention—each step reinforcing your confidence behind the wheel.

Advanced Brake Material Technologies Pushing Safety Boundaries

In the relentless pursuit of superior vehicle safety, cutting-edge brake materials are revolutionizing how we think about stopping power and durability. Contemporary innovations, such as carbon-ceramic composites, provide exceptional heat resistance and reduced brake fade, even under extreme conditions. These materials, used in high-performance sports cars and luxury models, offer a significant leap over traditional cast iron or semi-metallic pads, enabling drivers to maintain optimal braking response without compromise.

According to a comprehensive study by the Society of Automotive Engineers (SAE), the integration of these advanced compounds extends service intervals and minimizes rotor wear, translating into lower long-term maintenance costs. Mechanically, the challenge lies in ensuring compatibility with existing caliper hardware and brake system hydraulics, requiring meticulous calibration and professional expertise during installation. As vehicle technologies evolve, so too must our materials and techniques to stay ahead of safety risks.

Precision Calibration of Brake Hydraulic Systems for Consistent Performance

Achieving flawless brake operation demands more than just quality parts; it requires precise hydraulic calibration. Modern systems employ electronic brake force distribution (EBD) and anti-lock braking systems (ABS), which rely on sensors and control modules to modulate braking pressure dynamically. A subtle miscalibration can lead to uneven braking, increased stopping distances, or system failures. Advanced diagnostic tools, such as hydraulic pressure analyzers and electronic test benches, enable technicians to fine-tune these components with microscopic accuracy.

For instance, a slight imbalance in brake fluid pressure across wheels can cause pulling during deceleration—a dangerous scenario in emergency stops. High-end calibration ensures that each wheel receives optimal force, maintaining vehicle stability and driver confidence. Industry standards, like those from the National Highway Traffic Safety Administration (NHTSA), emphasize the importance of precision in hydraulic system maintenance to prevent catastrophic failures and prolong component lifespan.

What role do hydraulic fluid properties play in brake system longevity and safety?

Hydraulic fluid is the lifeblood of your brake system, transmitting force from the pedal to the calipers. Its properties—such as viscosity, boiling point, and moisture content—directly impact braking efficiency. Modern formulations incorporate synthetic additives that resist thermal breakdown and inhibit corrosion, but these benefits diminish over time. Regular testing of hydraulic fluid, including moisture analysis and contamination checks, is essential to maintain consistent performance.

Industry experts recommend replacing brake fluid every 2-3 years, depending on driving conditions and manufacturer specifications. Using high-quality, OEM-approved fluids ensures compatibility with advanced brake components and prevents issues like vapor lock or brake fade. For precise assessments, laboratories utilize refractometers and moisture meters to determine the fluid’s condition, facilitating proactive maintenance and safeguarding your vehicle’s safety integrity.

Interested in exploring how cutting-edge brake materials and calibration techniques can elevate your vehicle’s safety? Engage with trusted automotive professionals or join specialized forums to exchange insights and stay informed about the latest innovations. Remember, mastering these intricate elements is not just about compliance but about securing peace of mind on every journey.

Harnessing Cutting-Edge Brake Material Innovations for Enhanced Safety

In the relentless pursuit of automotive excellence, the development of advanced brake materials such as carbon-ceramic composites marks a pivotal leap forward. These materials, characterized by their remarkable heat resistance and minimal fade, enable vehicles to sustain optimal braking performance even under extreme stress. High-performance sports cars and luxury models increasingly leverage these innovations, setting new standards in safety and durability.

According to a detailed report by the Society of Automotive Engineers (SAE), integrating these materials significantly extends service intervals and reduces rotor wear, translating into lower maintenance costs and heightened reliability. However, their successful implementation demands meticulous calibration and compatibility checks with existing brake hardware, underscoring the importance of expert installation and ongoing system assessments.

Refining Hydraulic Brake Systems Through Precision Calibration

Achieving consistent and reliable braking performance hinges on the precise calibration of hydraulic systems, especially with modern electronic enhancements like EBD and ABS. Slight deviations in hydraulic pressure distribution can result in uneven braking, increased stopping distances, or even system failure. Advanced diagnostic tools—such as hydraulic pressure analyzers and electronic test benches—permit technicians to fine-tune these components with microscopic accuracy, ensuring optimal force distribution across all wheels.

For example, imbalance in brake fluid pressure can cause vehicle pulling during deceleration, jeopardizing safety. High-precision calibration aligns with standards from authorities like the National Highway Traffic Safety Administration (NHTSA), emphasizing that meticulous hydraulic maintenance is vital for safety and longevity.

How Do Hydraulic Fluid Properties Impact Long-Term Brake System Performance?

Hydraulic fluid acts as the vital conduit transmitting pedal force to the brake calipers. Its properties—viscosity, boiling point, and moisture content—directly influence braking efficiency and system integrity. Modern synthetics with superior thermal stability and corrosion inhibitors are essential, but their efficacy diminishes over time. Regular testing, including moisture content analysis, helps maintain ideal fluid conditions, preventing vapor lock and corrosion.

Industry guidelines recommend replacing brake fluid every 2-3 years, with laboratories employing refractometers and moisture meters to assess fluid health. This proactive approach ensures that brake systems operate under optimal conditions, safeguarding driver safety and vehicle reliability.

Integrating Scientific Insights for Long-Term Brake System Resilience

For those seeking to elevate their vehicle’s safety protocols, embracing scientific advancements in materials and diagnostics is crucial. Ultrasonic testing, for instance, can detect hidden rotor cracks or caliper issues before they manifest as failures. Such proactive diagnostics empower technicians to address problems early, maintaining system integrity through demanding driving conditions.

Engaging with trusted automotive specialists and staying abreast of innovations via industry publications can dramatically improve maintenance outcomes. Remember, the key to enduring safety lies in continuous learning and strategic intervention, with expert guidance playing a central role.

Optimizing Brake System Functionality Through Regular Monitoring

Monitoring subtle signs like pedal pulsations, pulling, or uneven wear patterns enables early detection of underlying issues. Regular inspections, coupled with diagnostic checks, prevent minor problems from escalating into critical failures. Recognizing symptoms such as faint vibrations or unusual noises can prompt timely interventions, preserving brake system health and driver confidence.

What Are the Most Effective Strategies to Prevent Brake System Failures?

Preventative maintenance strategies include routine fluid replacements, rotor resurfacing, and caliper inspections, all tailored to the vehicle’s usage profile. Upgrading to high-performance pads and rotors suited to your driving style can further enhance safety. Incorporating advanced diagnostic tools allows for precise adjustments, ensuring each component functions harmoniously. Adopting these strategies not only mitigates failure risks but also prolongs component lifespan, ultimately saving costs and enhancing safety.

For in-depth insights on staying ahead of brake system deterioration, consult trusted resources like brake service secrets. Building a collaborative relationship with reputable mechanics and asking targeted questions—such as those found in getting the most from your mechanic—are essential steps toward vehicle longevity and safety assurance.

By embracing these advanced maintenance techniques and scientific insights, you can ensure your vehicle remains a bastion of safety and performance amidst evolving automotive challenges. Invest in expertise today for a safer, more reliable driving experience tomorrow.

Expert Strategies for Superior Brake Performance

Implementing high-precision calibration of hydraulic systems ensures consistent braking power, especially in modern vehicles equipped with electronic brake force distribution and anti-lock systems. This meticulous approach minimizes uneven wear and maximizes safety under demanding conditions.

Precision Calibration Offers Critical Edge

Fine-tuning hydraulic pressure with advanced diagnostic tools such as electronic test benches helps prevent issues like pulling during stops and reduces the risk of catastrophic failures. Regular calibration aligned with industry standards guarantees optimal force distribution and enhances vehicle stability.

Innovations in Brake Material Technologies

Emerging materials like carbon-ceramic composites provide exceptional heat resistance and durability, extending service intervals and reducing rotor wear. These advancements are particularly valuable in high-performance and luxury vehicles, elevating safety and reliability.

Advanced Brake Fluid Testing Safeguards

Routine moisture content analysis and contamination checks using state-of-the-art laboratory tools help maintain brake fluid integrity, preventing vapor lock and corrosion. Timely fluid replacement, based on precise testing, preserves hydraulic efficiency and safety margins.

Curated Resources for Deep Expertise

- Society of Automotive Engineers (SAE): Offers research and standards on brake material innovations and system calibration techniques, essential for industry professionals.

- NHTSA: Provides authoritative safety guidelines and inspection protocols vital for maintaining brake system integrity.

- Automotive Diagnostic Journals: Publish cutting-edge studies on hydraulic testing and new material applications, supporting continuous learning.

Final Reflection from a Leading Expert

In the realm of auto safety, mastering advanced brake maintenance and calibration strategies elevates vehicle reliability and driver confidence. As technology evolves, staying informed about innovative materials and diagnostic techniques becomes essential. Engaging with trusted resources and maintaining a proactive maintenance mindset ensures your vehicle remains a symbol of safety and performance. For those committed to excellence, continuous education and expert collaboration are the keys to long-term trust and safety on every journey.