Elevating Vehicle Safety Through Precision Maintenance

In the realm of automotive care, the pursuit of reliability hinges on meticulous tune-up and brake maintenance strategies rooted in expert knowledge. As vehicles become more sophisticated, understanding the nuances of engine performance and brake system integrity is essential for ensuring safety, efficiency, and longevity. This article explores advanced methodologies and insights that elevate standard maintenance practices to a professional level, enabling drivers and mechanics alike to safeguard their journeys with confidence.

Leveraging Diagnostic Data for Proactive Tune-Ups

Modern vehicles are equipped with comprehensive diagnostic systems that provide real-time data critical for preemptive maintenance. Utilizing OBD-II scanners and advanced diagnostic tools allows technicians to identify subtle engine performance anomalies before they evolve into costly failures. Integrating these insights into routine tune-up protocols ensures optimal fuel economy, reduced emissions, and enhanced engine responsiveness, thereby reinforcing vehicle reliability under diverse driving conditions.

The Role of Lubrication and Fuel System Optimization in Reliability

High-quality lubricants and precise fuel system calibration are often underestimated in their impact on vehicle dependability. Advanced synthetic oils with tailored additive packages minimize engine wear, especially under extreme temperature fluctuations. Concurrently, optimizing fuel injectors and intake systems through professional cleaning or calibration ensures efficient combustion, reducing stress on engine components and extending service intervals. Such precision-focused practices are vital for maintaining peak performance and preventing degradation over time.

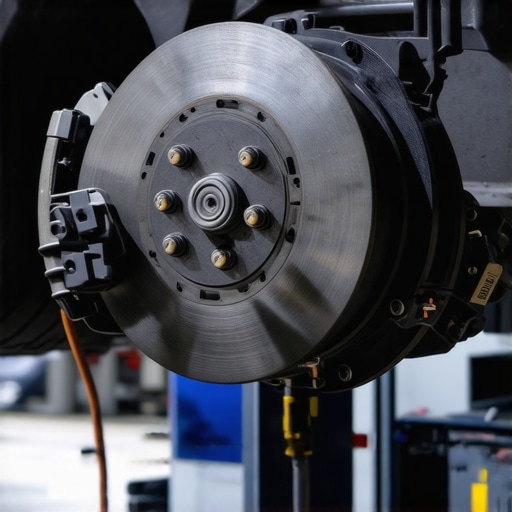

Innovative Brake Maintenance for Long-Term Safety

Brake systems require more than periodic pad replacements. Implementing advanced brake maintenance involves disc and drum refinishing, hydraulic system flushing, and the use of high-performance brake fluids. Regular inspection of brake lines, sensors, and calipers by skilled technicians prevents potential failures. Additionally, integrating anti-lock braking system (ABS) diagnostics and calibration into routine checks enhances safety, especially in emergency scenarios, by ensuring all components operate harmoniously and reliably.

What Are the Most Overlooked Factors in Brake System Longevity?

One often-overlooked aspect is the impact of environmental conditions such as road salt, humidity, and temperature extremes on brake components. Corrosion and moisture ingress can compromise the integrity of hydraulic and electronic parts, leading to delayed responses or failure. Experts recommend proactive measures like corrosion-resistant coatings and frequent fluid testing. Can integrating real-time monitoring sensors further enhance brake system longevity? This is an area ripe for innovation and continuous improvement, driven by advances in automotive sensor technology.

For those committed to achieving the highest standards of vehicle safety, exploring comprehensive resources is invaluable. Check out Brake Maintenance Hacks to Prevent Costly Failures for practical tips on extending brake lifespan, and consider consulting with a trusted mechanic from How to Choose a Skilled Mechanic You Can Trust to ensure your vehicle receives expert care. According to a study published in the Journal of Automotive Engineering, proactive maintenance based on diagnostic analytics significantly reduces the likelihood of breakdowns and enhances overall vehicle reliability (source: SAE International).

Unlocking the Power of Precision in Brake System Diagnostics

Advanced diagnostic tools have revolutionized how experts approach brake maintenance, enabling a deeper understanding of system health beyond simple visual inspections. Incorporating technologies like electronic brake force distribution (EBD) sensors and real-time hydraulic pressure monitoring allows technicians to detect subtle irregularities that could signal impending failure. This proactive approach minimizes downtime and prevents costly repairs, making it essential for those committed to vehicle safety.

Why Routine Calibration Keeps Your Brake System in Top Shape

Many drivers underestimate the importance of regular calibration, believing that brake pads or fluid replacements are sufficient. However, calibration ensures that sensors, ABS modules, and electronic brake controllers function in harmony. Proper calibration not only enhances safety but also extends the lifespan of brake components, reducing the likelihood of uneven wear or response delays. For a detailed guide on how to optimize your brake system, visit Brake Maintenance Hacks to Prevent Costly Failures.

How Do You Know Your Brake System Is Truly Ready for the Road?

While routine inspections are vital, expert evaluation involves testing for brake fluid contamination, pad thickness, rotor condition, and electronic system functionality. An often-overlooked factor is the influence of environmental stressors, such as road salt and humidity, which accelerate corrosion and component wear. Regularly scheduled professional assessments incorporating advanced testing methods can catch issues early, maintaining safety and reliability. Could integrating IoT-enabled sensors for continuous monitoring revolutionize brake maintenance? This is a promising avenue for the future, driven by ongoing innovations in automotive sensor technology.

For those seeking to deepen their understanding of reliable auto care, consider exploring Auto Repair Trust and Expert Tips for Reliable Brake Tune-Ups. Sharing insights and experiences in the comments can also foster a community dedicated to safer driving practices. Remember, partnering with a skilled mechanic is crucial—learn how to find one at How to Choose a Skilled Mechanic You Can Trust.

Why Cutting-Edge Diagnostics Are a Game-Changer for Brake Durability

In the fast-evolving landscape of automotive technology, reliance on traditional inspection methods no longer suffices for ensuring brake system longevity. Modern vehicles integrate complex electronic control units (ECUs) and sensors that demand sophisticated diagnostic techniques. Advanced diagnostic tools, such as oscilloscopes and CAN bus analyzers, enable technicians to interpret minute electrical and hydraulic signals, revealing hidden issues before they manifest as costly failures.

For example, real-time monitoring of electronic brake force distribution (EBD) and anti-lock braking system (ABS) sensors helps identify anomalies like uneven pressure or sensor drift, which can compromise safety. Integrating these diagnostics into routine maintenance routines dramatically enhances predictive maintenance capabilities, reducing unexpected breakdowns and extending component lifespan.

How Can Continuous Monitoring Sensors Transform Brake Maintenance?

Emerging sensor technologies, including IoT-enabled devices, promise to revolutionize brake health management. These sensors can continuously track parameters such as rotor temperature, pad wear, hydraulic pressure, and fluid quality, transmitting data to centralized systems for analysis. This constant stream of information allows for proactive interventions—replacing pads before they reach critical wear levels or flushing brake fluid before contamination causes corrosion or response delays.

According to a 2022 SAE International report, integrating IoT sensors in vehicle brake systems can decrease maintenance costs by up to 30% while significantly improving safety margins. Such innovations enable fleet managers and individual vehicle owners alike to optimize maintenance schedules based on real-world usage data rather than fixed intervals, fostering a paradigm shift toward predictive auto care.

Mastering Calibration for Peak Brake Performance

While many focus on replacing worn components, calibration ensures that electronic and hydraulic systems work harmoniously. Proper calibration of sensors, controllers, and actuators guarantees that brake responses are accurate and consistent. For instance, misaligned ABS modules can lead to uneven braking or pedal pulsation, diminishing driver confidence and safety.

Advanced calibration techniques involve not just factory resets but also dynamic adjustments based on vehicle load, driving conditions, and component aging. Using tools like high-precision wheel alignment systems and dynamic brake force measurement devices, technicians can fine-tune systems to exact specifications. This meticulous process prolongs component life and maintains optimal braking efficiency, particularly vital in high-performance or heavy-duty vehicles.

What Are the Nuanced Indicators of Hidden Brake System Failures?

Even with state-of-the-art diagnostics, some issues lurk beneath the surface. Subtle signs such as slight pedal travel deviations, unusual vibrations during braking, or inconsistent response under different loads can indicate early-stage problems like caliper sticking, hydraulic leaks, or electronic control failures. Recognizing these nuanced indicators requires a blend of technical expertise and experience, emphasizing the importance of continuous education for automotive professionals.

One particularly sophisticated diagnostic approach involves analyzing brake system response patterns under varying conditions, employing machine learning algorithms to detect anomalies. This proactive, data-driven methodology is gaining traction among high-end service centers aiming to preempt failures before they compromise safety.

If you’re eager to deepen your expertise in brake system diagnostics, explore resources such as the SAE International’s technical papers on brake sensor integration or consider advanced training programs offered by industry leaders. Staying ahead in auto safety means embracing innovation and precision at every maintenance stage.

Beyond Diagnostics: Strategic Maintenance for Brake System Resilience

Ultimately, diagnostics serve as a foundation for strategic maintenance planning. Regularly updating calibration settings, conducting comprehensive fluid testing, and employing environmentally resistant coatings on critical components are essential steps to fortify brake system resilience. These practices not only prevent failures but also ensure consistent performance across a vehicle’s lifespan.

Incorporating these advanced techniques into routine practices transforms brake maintenance from reactive repairs to proactive safeguarding. As automotive technology continues to evolve, so must our approaches—embracing the power of diagnostics, calibration, and continuous monitoring to deliver unmatched safety and reliability.

Harnessing the Power of Diagnostic Analytics for Brake Systems

In the quest for automotive excellence, leveraging sophisticated diagnostic data can transform routine brake maintenance into a predictive, precision-driven process. Cutting-edge tools such as CAN bus analyzers and high-resolution oscilloscopes enable technicians to interpret minute electrical and hydraulic signals, unveiling hidden anomalies before they manifest as costly failures. This proactive approach not only enhances safety but also optimizes maintenance schedules, ensuring vehicles operate at peak performance under diverse conditions.

Innovations in Continuous Monitoring and IoT Integration

Emerging sensor technologies, especially IoT-enabled devices, are revolutionizing brake health management. These sensors continuously track critical parameters like rotor temperature, hydraulic pressure, and pad wear, transmitting real-time data to centralized systems. By analyzing this information, fleet managers and individual owners can anticipate component deterioration, scheduling interventions precisely when needed. According to SAE International, such integrations can reduce maintenance costs by up to 30% while significantly elevating safety standards.

Refining Calibration Techniques for Optimal Brake Response

Calibration extends beyond initial setup, requiring dynamic adjustments aligned with vehicle load, driving patterns, and aging components. Advanced calibration methods involve the use of high-precision wheel alignment and dynamic force measurement devices to fine-tune electronic controllers and hydraulic systems. Proper calibration ensures consistent brake responses, minimizes uneven wear, and prolongs the lifespan of critical components—especially vital in high-performance or commercial vehicles.

Detecting the Subtle Signs of Hidden Failures

Even with state-of-the-art diagnostics, some issues remain elusive without expert insight. Slight deviations in pedal travel, unusual vibrations, or inconsistent responses under varying loads often signal early-stage problems like caliper sticking, hydraulic leaks, or sensor drift. Recognizing these nuanced indicators demands continuous education and experience. Advanced data analysis techniques, including machine learning algorithms, are increasingly employed to identify these subtle patterns, enabling preemptive maintenance that safeguards safety and reduces downtime.

How Can Predictive Maintenance Algorithms Transform Brake Care?

Predictive maintenance algorithms, powered by AI and machine learning, analyze vast quantities of sensor data to forecast component failures before they occur. By continuously learning from operational trends, these systems can recommend precise maintenance actions, optimize repair timing, and prevent emergencies. Industry leaders like Bosch are pioneering such solutions, which promise to redefine automotive safety and efficiency in the coming decade. To stay ahead, automotive professionals should explore integrating these intelligent systems into their diagnostic repertoire.

Engaging with detailed, authoritative resources like SAE International’s technical papers on brake sensor integration can significantly elevate your expertise. Embrace these innovations to ensure your brake systems are resilient, reliable, and ready for tomorrow’s challenges.

Mastering the Art of Calibration to Maximize Safety

Accurate calibration of electronic and hydraulic brake components is crucial for maintaining optimal performance. This process involves meticulous adjustment of sensors, controllers, and actuators, considering variables such as load conditions and environmental factors. Utilizing dynamic calibration tools, including high-precision wheel alignment systems and force measurement devices, ensures brake responses are uniform and predictable. Such precision not only extends component lifespan but also enhances safety, especially in demanding driving scenarios.

Identifying the Quiet Indicators of System Deterioration

Beyond obvious malfunctions, subtle signs like slight pedal travel variations, faint vibrations, or inconsistent braking feel can indicate early deterioration such as caliper corrosion, hydraulic leaks, or electronic control issues. Recognizing these indicators requires a blend of technical acumen and ongoing professional development. Incorporating machine learning-based response pattern analysis into diagnostic routines can further improve early detection, ultimately preserving brake integrity and driver safety.

If you’re committed to elevating your brake maintenance expertise, exploring SAE International’s comprehensive technical resources and participating in specialized training programs can provide invaluable insights. Staying abreast of technological advancements ensures your skills remain sharp and your vehicle’s safety uncompromised.

Expert Insights Elevate Brake Maintenance

Professionals in automotive safety recognize that meticulous calibration and diagnostic precision are the cornerstones of long-lasting brake systems. Regularly updating calibration settings in response to vehicle load changes and environmental conditions ensures consistent braking performance. Cutting-edge diagnostic tools, including CAN bus analyzers and high-resolution oscilloscopes, enable technicians to detect minute anomalies, preventing costly failures before they occur.

Sensor Technology and Continuous Monitoring

Emerging IoT-enabled sensors offer real-time data on rotor temperature, hydraulic pressure, and pad wear, transforming reactive maintenance into proactive care. These technologies allow for predictive interventions, such as replacing pads before critical wear or flushing brake fluid preemptively, significantly reducing downtime and enhancing safety margins. Industry reports suggest that integrating such sensors can cut maintenance costs by up to 30% while elevating vehicle reliability.

Strategic Calibration for Peak Performance

Dynamic calibration extends beyond initial setup, requiring ongoing adjustments tailored to operational conditions. Techniques utilizing high-precision wheel alignment and force measurement devices help fine-tune electronic controllers and hydraulic systems, ensuring uniform response and prolonging component lifespan. This approach is especially vital for high-performance or commercial vehicles subjected to demanding driving environments.

Detecting Subtle Warning Signs

Subtle indicators such as minor pedal travel deviations, vibrations, or inconsistent responses during braking can reveal early-stage problems like caliper sticking, hydraulic leaks, or sensor drift. Recognizing these signs demands expert knowledge and continuous professional development. Advanced machine learning algorithms analyzing response patterns further enhance early detection, enabling maintenance that prioritizes safety and minimizes unexpected failures.

Curated Resources for Deep Expertise

- SAE International Technical Papers on Brake Sensor Integration: Offers in-depth analysis and latest advancements in sensor technology and diagnostics.

- Automotive Diagnostic Equipment Manufacturers’ Guides: Provides technical manuals and best practices for utilizing advanced diagnostic tools effectively.

- Industry Conferences and Workshops: Facilitate continuous learning and exposure to emerging trends in automotive brake systems.

- Specialized Training Programs by Certified Institutions: Enhance skills in calibration, sensor integration, and predictive maintenance.

Final Perspective on Brake System Mastery

In today’s automotive landscape, mastering advanced brake maintenance strategies is essential for ensuring vehicle safety and reliability. The integration of innovative diagnostic tools, sensor technology, and expert calibration techniques transforms routine checks into proactive, precision-driven processes. By embracing these high-level practices, automotive professionals can significantly reduce failures, extend component life, and provide unparalleled safety assurance. Engage with these resources, share your insights, and continue elevating your expertise—because in the realm of vehicle safety, excellence is non-negotiable.