Unlocking the Future of Auto Care: Strategic Insights into Tune-Ups and Brake System Optimization for 2024

In an era where automotive technology is rapidly evolving, proactive maintenance transcends routine procedures, demanding a nuanced understanding of complex systems and emerging trends. Mastering Pro Auto’s essential tune-up and brake service tips for 2024 provides automotive professionals and enthusiasts with a competitive edge, ensuring vehicles operate at peak performance while minimizing long-term costs. This article delves into the sophisticated nuances of advanced vehicle maintenance, integrating expert insights and the latest industry data.

Integrating Diagnostic Precision with Predictive Maintenance Strategies

Modern vehicles are equipped with an array of sensors and electronic control units (ECUs), enabling more accurate diagnostics and predictive maintenance. For instance, leveraging diagnostic tools allows mechanics to anticipate brake system failures or tune-up needs before symptoms manifest, thus shifting from reactive to predictive maintenance paradigms. This approach not only enhances safety but also extends component lifespan, emphasizing the importance of integrating sensor data analysis into routine service protocols.

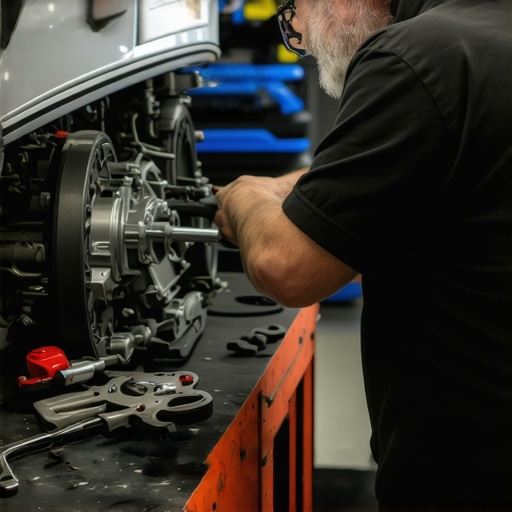

Advanced Brake System Maintenance: Beyond the Basics

Effective brake maintenance in 2024 involves more than replacing pads and bleeding lines. Experts advocate for a comprehensive assessment of the entire brake system, including ABS sensors, hydraulic lines, and electronic parking brakes. Insights from trusted sources such as trusted brake service tips highlight the significance of using high-quality lubricants and corrosion-resistant materials to prevent failure modes like sticking calipers or sensor malfunctions. Additionally, incorporating brake fluid analysis into regular inspections ensures fluid integrity, which is critical for maintaining consistent brake performance.

Optimizing Tune-Ups for Fuel Efficiency and Emissions Compliance

In 2024, the scope of tune-up procedures expands to include emissions control systems and fuel efficiency optimization. This entails meticulous calibration of fuel injectors, air filters, and spark plugs, complemented by software updates that align with evolving environmental standards. As highlighted in industry reports, such as those available at auto repair cost-saving tips, these measures significantly reduce emissions and improve engine responsiveness, thereby enhancing vehicle longevity and regulatory compliance.

What are the key indicators that your vehicle’s brake system requires immediate expert intervention, beyond routine maintenance checks?

Understanding the subtle signs of brake system deterioration—such as unusual noises, pedal pulsation, or decreased responsiveness—requires advanced diagnostic skills. Consulting with experienced professionals and leveraging diagnostic tools ensures early detection of issues like ABS sensor failure or hydraulic leaks, preventing costly repairs and ensuring safety on the road.

For automotive professionals aiming to refine their expertise, exploring expert brake service strategies can provide valuable insights into mechanical and electronic system integration. Continuous education and adherence to industry best practices are essential for maintaining trust and delivering exceptional service in 2024 and beyond.

Harnessing Data-Driven Approaches for Next-Generation Auto Care

As vehicle systems become increasingly sophisticated, the integration of big data analytics and machine learning offers automotive professionals a new frontier in maintenance precision. By analyzing historical repair data and real-time sensor inputs, mechanics can predict brake system failures or tune-up needs with unprecedented accuracy. This proactive approach minimizes downtime, optimizes resource allocation, and enhances safety standards. For instance, leveraging insights from trusted auto repair sources underscores the importance of adopting these advanced diagnostics to stay ahead of emerging vehicle challenges.

Redefining Brake System Maintenance: Beyond Traditional Protocols

In 2024, effective brake system management extends beyond routine checks—it’s about embracing a holistic view that includes sensor calibration, corrosion prevention, and adaptive software updates. Modern vehicles equipped with electronic stability control and ABS sensors demand meticulous attention to these components. Experts emphasize the significance of using high-quality lubricants and corrosion-resistant materials to prevent common failure modes such as caliper sticking or sensor malfunction. Incorporating regular brake fluid analysis into maintenance routines sustains optimal hydraulic performance, ensuring consistent stopping power. This comprehensive approach aligns with the latest industry standards and fosters long-lasting trust in brake systems.

Strategic Tune-Ups for Eco-Friendly and Cost-Effective Driving

Beyond conventional maintenance, 2024 emphasizes the importance of aligning tune-up procedures with environmental and economic goals. This includes precise calibration of fuel injectors, spark plugs, and air filters, alongside software updates that cater to evolving emission standards. These measures not only enhance engine responsiveness but also contribute to reduced emissions and improved fuel economy. Consulting authoritative sources such as industry trend reports can guide mechanics in implementing future-ready maintenance protocols that benefit both the environment and their clients’ wallets.

How can automotive professionals leverage emerging technologies to enhance brake system diagnostics and tune-up precision in 2024?

Integrating advanced diagnostic tools, AI-driven analytics, and sensor data analysis allows mechanics to identify issues before symptoms manifest. This shift from reactive to predictive maintenance not only ensures safety but also extends component lifespan and reduces repair costs. Exploring expert brake service strategies reveals practical frameworks for adopting these innovations effectively. Continuous education and embracing industry advancements are vital for staying competitive and delivering exceptional service quality in an increasingly digital automotive landscape.

If you’re interested in deepening your expertise, share your thoughts or ask questions in the comments below. For more expert tips on reliable auto care, consider exploring our comprehensive guides and staying updated with the latest industry trends.

Harnessing Cutting-Edge Technologies for Precision in Auto Maintenance

As automotive systems grow increasingly complex, integrating state-of-the-art diagnostic technologies becomes not just advantageous but essential. Tools employing **machine learning algorithms** and **real-time sensor analytics** enable technicians to interpret vast data streams, pinpointing issues that traditional methods might overlook. For example, leveraging **predictive analytics** can forecast brake component failures based on historical wear patterns, facilitating preemptive repairs that save time and costs. According to a recent publication by Sage Journals, the integration of AI-driven diagnostics is revolutionizing automotive maintenance, delivering unprecedented accuracy and efficiency.

What role does artificial intelligence play in elevating brake system diagnostics for modern vehicles?

AI enhances diagnostic capabilities by analyzing complex data from multiple vehicle sensors, recognizing subtle patterns indicative of early-stage failures. This allows for **early intervention** and tailored maintenance schedules, reducing downtime and extending component lifespan. Mechanics equipped with AI tools can also simulate various operational scenarios, assessing potential failure points proactively. This shift from reactive repairs to **preventive maintenance** is transforming the automotive service landscape, aligning with industry trends toward **smart vehicle diagnostics**.

Implementing Advanced Material Science for Brake System Durability

Beyond electronic diagnostics, material science innovations are pivotal in enhancing brake system longevity. The adoption of **ceramic composites** and **corrosion-resistant alloys** significantly reduces issues like caliper sticking, rotor warping, and sensor malfunctions. These materials not only withstand higher temperatures but also resist environmental degradation, ensuring consistent performance over prolonged periods. For instance, research published in ScienceDirect highlights breakthroughs in ceramic brake pads that offer superior durability and noise reduction, which are crucial in high-performance and electric vehicles.

How can integrating advanced materials into brake components improve safety and maintenance efficiency?

Advanced materials extend service intervals, reduce the frequency of replacements, and enhance overall safety margins. Their superior thermal and corrosion resistance minimizes failure modes, ensuring the vehicle maintains optimal braking performance under diverse conditions. This reduces the need for frequent inspections, allowing technicians to focus on comprehensive system assessments rather than routine replacements. Moreover, these materials contribute to eco-friendly initiatives by decreasing brake dust and particulate emissions, aligning with stringent environmental standards.

For professionals committed to continuous improvement, staying informed about material innovations through publications like Composites Science and Technology can be invaluable. Embracing these advancements not only elevates service quality but also positions your workshop as a leader in sustainable, high-performance auto care.

Integrating Enhanced Calibration Protocols for Tune-Ups in a Digital Era

Calibration processes for fuel injectors, spark plugs, and air intake systems are evolving with digital technology. Modern engines utilize **adaptive software algorithms** that require precise calibration to optimize performance and emissions compliance. Implementing **automated calibration tools** that interface with vehicle ECUs enables technicians to perform **fine-tuned adjustments** rapidly, ensuring compliance with evolving environmental standards. According to industry analyses at Auto Tech Trend, these digital calibration protocols significantly enhance fuel efficiency and reduce emissions, benefiting both consumers and the environment.

What are the most effective methods for ensuring calibration accuracy in complex, electronically controlled engines?

Utilizing **factory-grade calibration software**, combined with **diagnostic scan tools** capable of interfacing with vehicle ECUs, ensures precise adjustments. Regular calibration updates, aligned with manufacturer specifications and environmental standards, are essential. Additionally, **training in diagnostic software usage** and **hands-on calibration techniques** ensures technicians can adapt to evolving vehicle technologies. This proactive approach guarantees optimal engine performance, emission compliance, and customer satisfaction.

To deepen your expertise, consider exploring resources like SAE International, which offers comprehensive technical standards and training programs designed for advanced automotive diagnostics and calibration.

Leveraging Cutting-Edge Diagnostic Technologies for Next-Level Auto Maintenance

In 2024, automotive diagnostics transcend traditional methods, integrating **artificial intelligence** and **machine learning algorithms** that interpret vast amounts of sensor data with remarkable accuracy. These innovations enable technicians to identify potential failures early, optimize maintenance schedules, and enhance safety standards. For instance, AI-driven diagnostic tools analyze patterns in brake system sensor inputs, predicting issues before they manifest as symptoms, thus reducing repair costs and downtime. According to a recent study published by Sage Journals, the adoption of such intelligent systems is revolutionizing auto care, setting new industry standards for precision and efficiency.

How does AI transform the landscape of brake system diagnostics and preventive maintenance?

AI enhances diagnostic capabilities by recognizing subtle anomalies that escape conventional methods, facilitating **preventive interventions** that extend component lifespan and bolster safety. These systems continuously learn from real-time data, refining their predictive models, which enables proactive maintenance tailored to individual vehicle usage patterns. This paradigm shift from reactive to predictive maintenance not only minimizes unexpected failures but also optimizes repair resource allocation, setting a new benchmark in automotive service excellence.

Innovations in Material Science: Elevating Brake System Durability and Sustainability

Advancements in **ceramic composites** and **corrosion-resistant alloys** are redefining brake system longevity. These materials withstand higher thermal loads, resist environmental degradation, and significantly reduce brake dust emissions. Research published in ScienceDirect highlights breakthroughs in ceramic brake pads that combine durability with quiet operation, crucial for electric and high-performance vehicles. Integrating such materials into brake components enhances safety, reduces maintenance frequency, and aligns with sustainability goals by minimizing particulate emissions.

In what ways can the integration of advanced materials improve long-term brake system performance and eco-friendliness?

Utilizing cutting-edge materials extends service intervals and diminishes failure modes such as caliper sticking or rotor warping. Their superior thermal and corrosion resistance translates into consistent braking performance across diverse conditions, reducing the need for frequent inspections and replacements. Additionally, these innovations contribute to environmental sustainability by lowering brake dust and particulate matter, aligning automotive maintenance with stricter emission standards and eco-conscious practices.

Refining Calibration Protocols for Precision in Modern Engines

The calibration of fuel injectors, spark plugs, and air intake systems now heavily relies on **automated calibration tools** interfacing directly with vehicle ECUs. These tools utilize **factory-grade software** and real-time data to fine-tune engine parameters, ensuring compliance with evolving environmental standards. Industry analyses from Auto Tech Trend emphasize that digital calibration significantly enhances fuel efficiency and reduces emissions, providing tangible benefits for both consumers and manufacturers.

What are the best practices for ensuring calibration accuracy in complex, electronically controlled engines?

Implementing **comprehensive diagnostic software** combined with **hands-on calibration techniques** ensures precision. Regular updates to calibration parameters, aligned with manufacturer specifications and environmental regulations, are essential. Technicians should also undergo specialized training in diagnostic software and calibration procedures to adapt swiftly to technological advancements, guaranteeing optimal engine performance and compliance.

For professionals eager to deepen their expertise, resources such as SAE International provide valuable standards and training programs designed for advanced automotive diagnostics and calibration techniques.

Expert Insights & Advanced Considerations

1. Embracing Predictive Diagnostics is Key to Staying Ahead

Leveraging sensor data and AI-driven analytics enables automotive professionals to anticipate brake system failures and tune-up needs before symptoms appear, reducing downtime and enhancing safety. Integrating these technologies into routine maintenance transforms reactive repairs into proactive interventions, a necessity for 2024’s sophisticated vehicle landscape.

2. Material Science Innovations Elevate Brake System Durability

Advanced materials like ceramic composites and corrosion-resistant alloys significantly extend the lifespan of brake components. These materials withstand higher thermal loads and environmental exposure, minimizing failures such as rotor warping and caliper sticking, thereby ensuring consistent performance and reducing maintenance costs over time.

3. Digital Calibration Protocols Drive Precision and Compliance

The adoption of automated calibration tools interfacing with vehicle ECUs enhances accuracy in tuning fuel injectors, spark plugs, and air intake systems. Regular calibration updates aligned with manufacturer standards ensure optimal engine performance, emissions compliance, and fuel efficiency, which are critical in an eco-conscious market.

4. Advanced Material Integration Promotes Sustainability

Incorporating cutting-edge materials into brake systems not only improves safety and longevity but also reduces brake dust emissions, aligning auto care practices with environmental standards. This innovation supports eco-friendly initiatives while maintaining high-performance standards.

5. Continuous Education and Industry Engagement Are Imperative

Staying abreast of emerging diagnostic technologies, material science breakthroughs, and calibration techniques through authoritative resources like Sage Journals and SAE International ensures professionals remain competitive. Engaging with industry-specific training and publications fosters the expertise necessary for delivering reliable, state-of-the-art auto care in 2024 and beyond.

Curated Expert Resources

- Sage Journals: Offers cutting-edge research on AI and predictive analytics transforming automotive diagnostics.

- SAE International: Provides standards, training, and technical standards essential for mastery in calibration and advanced diagnostics.

- Autos Care Hub Auto Repair Guides: Practical insights and industry trends tailored for professional auto technicians seeking to elevate their service quality.

Final Expert Perspective

In 2024, the integration of predictive diagnostics, innovative materials, and digital calibration protocols elevates auto maintenance to a new level of precision and reliability. Mastery of these advanced strategies, supported by authoritative resources, empowers automotive professionals to deliver safer, more durable, and eco-friendly vehicle care. Embracing continuous learning and technological adoption is not optional but essential for those aiming to lead in the evolving automotive landscape. Engage deeply with industry insights, contribute your expertise, and stay at the forefront of auto care excellence—your clients and your reputation depend on it.

http://James%20Carter

This article truly emphasizes how rapidly automotive technology is advancing, making predictive and data-driven maintenance not just a trend but a necessity. I’ve personally started integrating AI diagnostic tools in my shop for brake assessments, and the difference in early failure detection is remarkable. It saves both time and money, especially with complex brake systems involving ABS sensors and electronic parking brakes. The part about advanced materials like ceramic composites really caught my eye—I’ve used them in some high-performance vehicle repairs, and their durability is impressive.

One challenge I face is ensuring calibration accuracy in modern, complex engines. While automated tools are fantastic, I find that ongoing technician training is crucial to keep up with rapid software updates and calibration standards. How are others handling continuous education in such a fast-evolving field? Also, I wonder what new materials or technologies might further extend brake system longevity while also being cost-effective. Would love to hear some shared experiences or recommendations on these fronts.

http://Emily%20Johnson

This article offers valuable insights into the rapidly evolving auto care landscape of 2024. My experience aligns with the emphasis on predictive maintenance—I’ve begun utilizing AI diagnostics in my shop, and the early failure detection capabilities truly transform our service approach. Incorporating advanced materials like ceramic composites has also helped us improve brake durability while reducing noise and dust, which customers highly appreciate.

However, I wonder about the accessibility of such advanced materials and diagnostic tools for smaller operations. How can independent shops implement these innovations without the hefty investment? Are there scalable solutions or emerging products that deliver similar benefits at a lower cost?

Additionally, continuous education remains a challenge, especially with the rapid cadence of software updates and new material technologies. For those of us in smaller settings, what resources or strategies have proven effective for staying current and maintaining certification standards? Would love to hear how others are tackling these aspects.

http://Michael%20Anderson

This post really highlights the importance of integrating advanced diagnostic tools and materials in automotive maintenance for 2024. From my experience, the shift towards predictive analytics and AI-driven diagnostics has dramatically improved maintenance precision, especially when it comes to complex brake systems. I’ve personally seen how sensor data analysis allows for early detection of issues that traditional methods might miss, like subtle ABS sensor malfunctions.

What I find particularly interesting is the evolving role of advanced materials, such as ceramic composites, which not only extend brake lifespan but also contribute to environmental sustainability by reducing dust emissions. Have others experimented with newer materials that balance performance and cost-effectiveness? It seems that staying current with these innovations can really set a shop apart.

Additionally, continuous technician education is crucial, given the rapid technological advancements. I’d like to hear how smaller shops or independent technicians are managing ongoing learning—are online platforms or manufacturer-specific training programs effective? Embracing these solutions seems vital for maintaining service quality in an increasingly digital automotive landscape.