Elevating Vehicle Safety through Advanced Brake System Maintenance and Precision Auto Repairs

In the landscape of automotive care, a nuanced understanding of brake service and comprehensive repair strategies forms the backbone of ensuring sustained safety and performance. Precise diagnostics, rooted in mechanical expertise, allow mechanics to anticipate and address issues before they culminate in costly failures, thereby safeguarding drivers and prolonging vehicle lifespan. Recognizing that each component—from rotors to calipers—interacts within a complex system underscores the importance of tailored maintenance routines designed for longevity and reliability.

Unearthing the Layers of Effective Tune-Up Strategies for Modern Vehicles

Beyond the surface, the concept of a tune-up extends into holistic engine optimization, involving synchronized adjustments to spark plugs, ignition timing, and fuel systems. Advanced tune-up techniques, aligned with vehicle-specific specifications, can significantly boost fuel efficiency and reduce emissions, reflecting a deep integration of diagnostic analytics and mechanical adjustments. Emphasizing the importance of regular tune-ups, industry data indicates a notable decrease in breakdowns and repair costs over the vehicle’s lifespan.

How Do Contemporary Mechanical Diagnostics Revolutionize Auto Repair Efficacy?

Modern diagnostic tools, such as OBD-II scanners and laser alignment systems, have revolutionized the auto repair landscape by enabling precise, real-time problem identification. These technologies foster a proactive maintenance mindset, allowing mechanics to deliver targeted repairs that minimize time and resource expenditure, while maximizing safety outcomes. The integration of such tools underlines the shift towards data-driven, transparent service processes, building trust and credibility with discerning car owners.

What Are the Financial and Safety Implications of Delayed Brake Service or Subpar Tune-Ups?

Postponing critical brake service or neglecting routine tune-ups can exponentially increase repair costs and compromise safety. Studies suggest that immediate attention to signs of brake degradation—such as unusual noises or increased stopping distances—can prevent accidents and structural damage. Additionally, a vehicle with poorly maintained brakes or outdated tune-up configurations can experience reduced fuel economy and heightened emissions, impacting both the environment and owner expenses. Trusted sources, like the National Institute for Automotive Service Excellence, advocate for periodic inspections to uphold vehicle integrity.

In the quest for long-lasting performance, it’s imperative that consumers collaborate with qualified technicians, leveraging knowledge and technological assets to maintain their vehicles at peak operational standards. Exploring how advanced diagnostics and expert maintenance routines interconnect provides a pathway toward safer, more reliable driving experiences. To further refine your approach, consider consulting industry-specific insights such as pro brake service strategies deployed by leading professionals.

What Innovations in Brake Technology Will Define the Future of Auto Safety?

Embracing the latest breakthroughs in materials science and electronic monitoring, the automotive industry is on the cusp of transformative changes in brake systems that promise heightened safety and durability. Stay informed about emerging trends and contribute your expertise to ongoing discussions on enhancing vehicle reliability.

Engaging with specialized content and hands-on experience is essential for automotive professionals aiming to deliver superior service. Discover advanced techniques and expand your knowledge base by visiting cost-saving repair tips from industry experts.

Innovating Brake Materials for Enhanced Durability and Performance

One of the most exciting developments in brake technology revolves around advanced composite and ceramic materials that drastically reduce wear and heat build-up. These innovations not only extend the lifespan of brake components but also improve driving safety by providing more consistent braking responses under demanding conditions. Industry leaders are investing heavily in research to develop materials that resist warping, corrosion, and thermal degradation, making brake systems more resilient than ever. For mechanics and vehicle owners aiming to maximize brake longevity, understanding these material options is crucial for informed maintenance decisions.

Implementing Predictive Maintenance Through Smart Brake Monitoring

The future of brake system care leans heavily on sensor technology and data analytics. Smart brake pads embedded with wear sensors can communicate real-time status to onboard computers or external devices, enabling predictive maintenance strategies. This approach shifts the paradigm from routine scheduled checks to condition-based interventions, preventing unexpected failures and optimizing service intervals. Such innovations exemplify the integration of Internet of Things (IoT) solutions into automotive maintenance, facilitating a proactive approach that saves costs and enhances safety. To explore this trend further, consider consulting resources on future automotive innovations.

Can Electronic Brake Systems Keep Pace with Mechanical Reliability Concerns?

As vehicles increasingly adopt electronic and hybrid brake systems, many experts question whether these technologies can match the proven durability of traditional mechanical brakes over time. While electronic brake-force distribution and ABS technology dramatically improve safety during dynamic driving, their reliance on sensors and computer algorithms introduces new points of potential failure. Ensuring the reliability of these systems requires rigorous diagnostics and regular software updates, emphasizing the importance of continuous technician education and equipment investment. Seeking expert guidance on maintaining electronic brake components is vital—learn more about diagnosing common auto problems effectively.

If you’re interested in staying at the forefront of automotive repair innovations, engaging with professional networks and industry workshops can provide invaluable insights and hands-on experience. For tailored advice on your vehicle’s brake system, don’t hesitate to contact our expert team today.

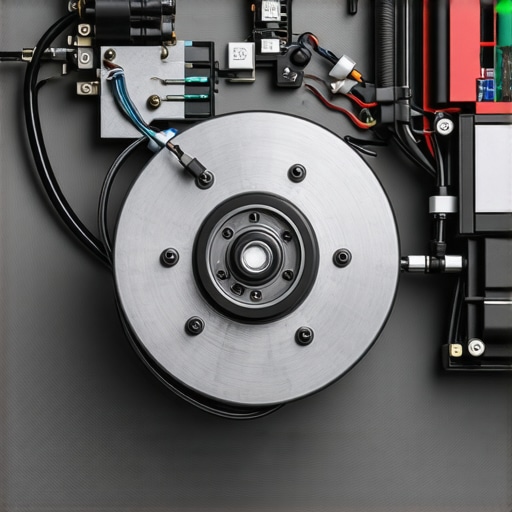

Revolutionary Sensor Integration Elevates Brake System Monitoring

One of the most groundbreaking innovations in modern auto safety is the deployment of sensor-integrated brake components, transforming passive systems into intelligent safety networks. These sensors continuously monitor parameters like pad wear, rotor temperature, and hydraulic pressure, transmitting real-time data to onboard control units. This data enables proactive maintenance alerts, minimizing unexpected failures and optimizing repair schedules, ultimately safeguarding drivers and reducing repair costs.

How Does Sensor Data Tie into Predictive Maintenance Frameworks?

Leveraging sensor data through advanced analytics and machine learning algorithms creates powerful predictive maintenance models. By analyzing patterns such as temperature fluctuations or wear rates over time, technicians can anticipate component failures well before they manifest as safety hazards. Industries like aerospace have long adopted similar predictive models, and adaptive transportation sectors are now integrating these principles into everyday vehicle maintenance, as highlighted in recent SAE International publications (SAE Technical Papers).

Implementing these systems involves integrating IoT connectivity, which facilitates seamless communication between your vehicle’s brake system and external diagnostic platforms—an evolution towards truly connected automotive ecosystems.

Material Science Breakthroughs Promise Longer-Lasting Brakes

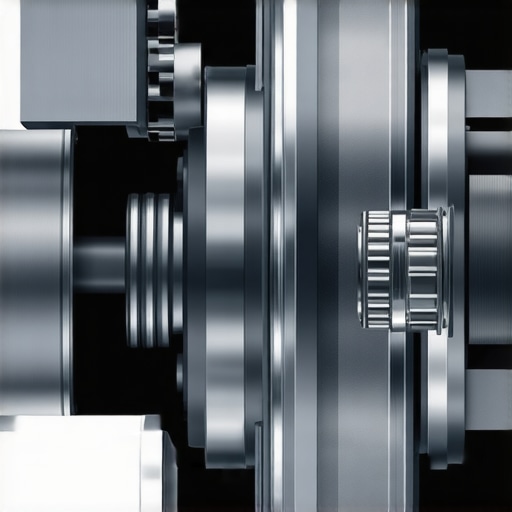

Exploring beyond traditional brake pad compositions, researchers are developing composite materials such as carbon-ceramic hybrids that withstand higher temperatures, resist corrosion, and exhibit lower wear rates. These materials are not only more durable but also provide improved thermal management, dramatically reducing fade under strenuous conditions like mountainous driving or heavy towing. Automakers investing in such materials can offer consumers vehicles with lower lifecycle costs, enhanced safety margins, and reduced environmental footprints due to decreased particulate generation from brake wear.

What Challenges Remain in Scaling Advanced Brake Material Adoption?

While the benefits are clear, integrating new materials into mass production presents challenges related to cost, manufacturing complexity, and compatibility with existing systems. Addressing these hurdles requires a multidisciplinary approach involving materials science, manufacturing engineering, and supply chain optimization. Industry collaborations, such as partnerships between research institutions and automotive giants—exemplified by the U.S. Department of Energy’s Vehicle Technologies Office—are pivotal for overcoming barriers and accelerating adoption (DOE VTO).

Understanding these developments empowers technicians and engineers to recommend and implement cutting-edge solutions that elevate vehicle safety, longevity, and environmental responsibility. To stay abreast of these innovations, consider subscribing to leading industry journals and participating in specialized training sessions that focus on material science advancements and diagnostic system integration.

Integrating Artificial Intelligence into Brake System Diagnostics

The future of auto diagnostics is increasingly linked with artificial intelligence (AI), enabling systems to learn from historical data and improve their predictive accuracy over time. AI algorithms can sift through vast data pools—sensor outputs, repair histories, driving conditions—to identify subtle patterns indicative of impending failures. This capability allows maintenance teams to prioritize interventions, allocate resources efficiently, and customize maintenance schedules tailored to individual vehicles’ operational profiles.

Furthermore, AI-powered virtual assistants can guide technicians through complex diagnostics, ensuring consistency across service centers and reducing human error. As automotive AI matures, standards and best practices are emerging, guided by organizations such as the International Organization for Standardization (ISO), which emphasizes safety, interoperability, and data security (ISO TC 22/ SC 37).

Engaging with these technological trends requires continuous learning and adaptation. Industry leaders recommend integrating AI literacy into technician training programs, fostering a new generation equipped to manage sophisticated vehicle systems effectively. To deepen your expertise, explore advanced certifications in automotive data analytics and AI-driven diagnostics offered by reputable technical institutes.

How Are Modern Materials Transforming Brake System Durability

The integration of advanced composite materials, such as carbon-ceramic composites, is revolutionizing brake components by offering unprecedented resistance to heat, wear, and corrosion. These innovations extend service life, reduce maintenance costs, and enhance safety during demanding driving conditions, positioning themselves as critical assets for high-performance and luxury vehicles.

Revolutionizing Maintenance with Real-Time Brake Monitoring

By embedding sensors directly into brake pads and rotors, manufacturers enable real-time health assessments, allowing proactive interventions that prevent catastrophic failures. This sensor-driven approach aligns with the broader industry shift towards predictive maintenance, minimizing downtime and fostering trust through transparency. The collective adoption of IoT-based diagnostics is paving the way for a more interconnected, intelligent automotive ecosystem.

< >

>

Can Artificial Intelligence Ratings Anticipate Brake Failures?

AI algorithms analyze vast datasets—capturing variables like temperature spikes, pad wear patterns, and vehicle load—to predict potential failures before they manifest. This anticipatory insight grants technicians an invaluable window for intervention, greatly reducing safety risks and costs associated with unanticipated repairs. As AI systems become more sophisticated, their integration into brake diagnostics will become essential for fleet safety management and individual vehicle care.

Bridging Mechatronics and Safety with Electronic Brake Systems

The evolution from mechanical to electronically-controlled braking mechanisms incorporates features like anti-lock braking systems (ABS), electronic stability control (ESC), and brake-by-wire technology. While these systems dramatically improve handling and safety, they necessitate rigorous diagnostics to ensure reliability, especially since software malfunctions can be as critical as hardware failures. Maintaining a rigorous calibration protocol and leveraging specialized diagnostic tools are instrumental for technicians dedicated to safety-critical systems.

Future Outlook: Embedded Sensors and Autonomous Brake Optimization

Emerging research points toward the deployment of smart sensors capable of not only monitoring wear but also optimizing braking force distribution dynamically. This autonomous adjustment enhances safety during complex maneuvers, such as emergency braking or adverse weather conditions. These systems require sophisticated control algorithms and real-time data processing, highlighting the significance of interdisciplinary expertise in aerospace-grade electronics and automotive engineering.

Where Will Brake Safety Innovations Lead Industry Standards?

The confluence of material science breakthroughs, sensor integration, and AI analytics is steering the automotive industry toward more resilient and intelligent brake systems. Regulatory bodies and industry consortia are actively shaping standards that prioritize safety, longevity, and environmental sustainability. Engaging with these developments through continued education and certification ensures that automotive professionals remain at the forefront of this transformative era. For more on cutting-edge standards and the latest technological advances, consult authoritative sources like the SAE International publications (SAE Technical Papers).

Expert Insights & Advanced Considerations

Embrace Integration of AI for Predictive Maintenance

Leveraging artificial intelligence in brake diagnostics and tune-up procedures enables mechanics to anticipate issues before symptoms manifest, reducing downtime and enhancing safety standards.

Prioritize Material Innovation for Enhanced Durability

Adopting advanced composite and ceramic materials in brake components promises longer lifespan and consistent performance, especially under demanding driving conditions.

Harness Sensor Technology for Real-Time Monitoring

Embedding wear sensors and IoT connectivity into brake systems facilitates proactive maintenance, minimizing unexpected failures and fostering trust.

Optimize Service Efficiency with Data-Driven Diagnostics

Utilizing state-of-the-art diagnostic tools streamlines repair processes, ensures precision, and elevates overall customer satisfaction.

Focus on Custom Solutions for Vehicle Longevity

Understanding specific vehicle profiles and tailoring maintenance routines enhances reliability and extends the lifespan of critical components.

Curated Expert Resources

- SAE International Publications: Offers comprehensive technical papers and standards shaping automotive safety and innovations.

- Automotive Technology Journals: Provides the latest research on materials science, electronics, and AI applications in vehicle maintenance.

- Industry Workshops and Certification Programs: Engages professionals in hands-on advanced training on emerging brake materials and diagnostic techniques.

Final Expert Perspective

In the realm of automotive maintenance, especially concerning brake systems and tune-ups, staying ahead of technological advancements is paramount. Advanced diagnostic tools, innovative materials, and sensor integration not only improve safety and reliability but also build consumer confidence. Recognizing and implementing these high-level strategies transforms routine repairs into proactive, system-enhancing processes. For those committed to excellence, continuously exploring trusted resources and sharing insights within professional networks is vital. Ready to elevate your expertise? Connect with us today and lead the industry forward.